When it comes to strength and versatility, few materials stand out like 4140 steel. This alloy is a powerhouse known for its exceptional properties, making it a staple across diverse industries. (the Strength of 4140 Steel)

A Mighty Contender

4140 steel’s robust mechanical performance has caught the attention of engineers, designers, and manufacturers. Its blend of strength, ductility, and toughness makes it a go-to choice for components under heavy loads and extreme conditions.

Microstructural Marvel

Microscopy reveals the secret behind 4140 steel’s might – a fine-grained mix of ferrite and tempered martensite. The presence of elements like chromium and molybdenum plays a pivotal role in shaping this strong microstructure.

Strength in Every Strain

Tensile, hardness, and impact tests put 4140 steel through its paces. The results? Impressive tensile strength, remarkable hardness, and a knack for withstanding impacts. It’s a material built for reliability and endurance.

Heat’s Transformative Touch

Heat treatment is like a magic touch for 4140 steel. Quenching and tempering processes reshape its microstructure, boosting toughness and ductility without compromising strength. Mastering these treatments is key to unlocking its full potential.

Beyond Boundaries

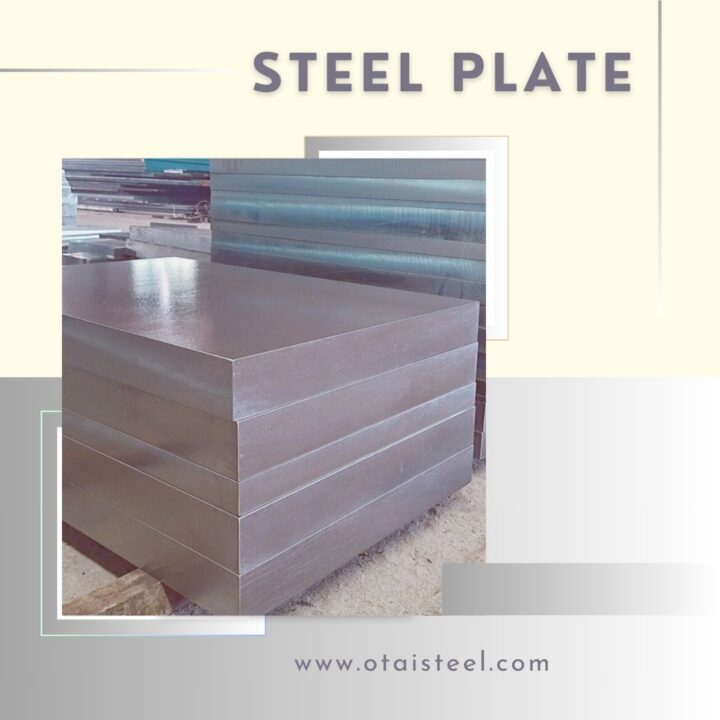

4140 steel is a true all-rounder. It’s the backbone of heavy machinery, the force behind gears and crankshafts, and the unsung hero in tools and dies. Its adaptability knows no bounds.

Delving into the properties of 4140 steel reveals a material that’s more than just metal. It’s a symbol of strength, reliability, and innovation. As industries advance, so does our understanding of this alloy, propelling us to new frontiers of engineering and design.