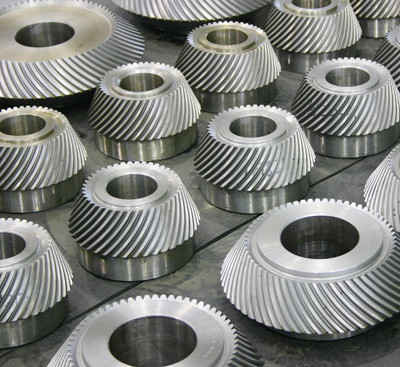

Unlocking Quality Solutions: Partnering with OTAI for Premium 4140 steel machinery parts

Introduction: Hey there, fellow steel enthusiasts! Today, we’re diving into a common challenge faced by our friends over in Mexico – quality issues in the production of steel machinery parts. But fear not, because OTAI is here to offer top-notch solutions tailored to meet your needs!

Spotlight on the Situation:

Picture this: our amigos down in Mexico are facing a bit of a hiccup in their steel machinery parts production line. Here’s the scoop on what’s been causing them headaches:

1. Size Matters: First up, there’s a snag in getting those parts to the right size. It’s like trying to fit a square peg into a round hole – just doesn’t quite work out.

2. Strength Struggles: Then, there’s the issue of material strength. The parts ain’t holding up as they should, and that’s a real bummer when you need reliability in your machinery.

3. Composition Conundrum: Last but not least, there’s been some talk about the materials not quite hitting the mark in terms of composition. It’s like baking a cake but forgetting the sugar – things just ain’t turning out right.

Navigating the Conflict: Now, here’s where things get interesting. Despite their best efforts, the current supplier ain’t able to iron out these wrinkles. Our amigos are in a bit of a bind and are on the hunt for a new partner who can deliver the goods.

Presenting the OTAI Advantage:

Enter OTAI – your go-to partner for quality steel solutions! Here’s how we’re stepping in to save the day:

1. Precision Delivery: We understand the importance of getting those parts just right. That’s why we’re committed to meticulous size checks before every delivery. No more guessing games – just precision, every time.

2. Strength Boost: Weak materials? Not on our watch! We’ll customize our heat treatment process to ensure your parts meet the strength requirements you demand. When it comes to durability, we’ve got you covered.

3. Composition Confidence: We leave no stone unturned when it comes to quality assurance. Our chemical composition analysis guarantees that your parts meet industry standards and contractual obligations. You can trust that what you’re getting is top-notch quality, through and through.

Partnering with OTAI for Premium 4140 steel machinery parts

In the world of steel production, quality is non-negotiable. With OTAI by your side, you can bid farewell to those pesky production issues and hello to seamless operations and top-tier results. Let’s partner up and pave the way for excellence together – because when it comes to quality steel, OTAI delivers, every time.