Why 4140 Steel Plate Hardness Matters

Why 4140 Steel Plate Hardness Matters

Are you a steel wholesaler or distributor looking for top-quality steel plates? You might have heard about 4140 steel. But do you know why the hardness of 4140 steel plate is so important? Let’s talk about why 4140 steel’s hardness matters and why OTAI is your best choice for 4140 steel plates.

What is 4140 Steel?

4140 steel is a special kind of steel. It’s made from chromium and molybdenum, making it very strong and tough. One of the best things about 4140 steel is its hardness. This steel can be heat-treated to become very hard, which is great for many industries.

Why Hardness is Important

1. More Durable

The harder the steel, the more durable it is. Hard steel can resist wear and tear better. This means that 4140 steel plates will last longer, even when used a lot. For industries like automotive and machinery manufacturing, this is a big deal. Using 4140 steel means your parts will last longer.

2. Better Performance

Hard steel performs better. It can handle more stress without getting bent or damaged. This makes 4140 steel perfect for high-stress jobs. Whether you’re making gears, shafts, or drilling tools, 4140 steel’s hardness means your products will work better and last longer.

3. Cost-Effective

Using harder steel can save you money over time. Because 4140 steel plates are so durable, you won’t need to replace them as often. This cuts down on maintenance costs and downtime. So, even if 4140 steel costs more upfront, it saves you money in the long run.

Why Choose OTAI for 4140 Steel?

At OTAI, we offer top-quality 4140 steel plates with some great benefits:

1. Always in Stock

We keep a large stock of 4140 steel plates in many sizes. Need a special size? We can customize it quickly. Our plates are ready to ship, so you get your order fast.

2. Great Packaging

We take care of your steel from our warehouse to your door. Our packaging options include:

- Strapped Packaging: Keeps your order secure.

- Wooden Box Packaging: Gives extra protection.

- Rust-Proof Packaging: Prevents rust during shipping.

3. Trusted by Big Companies

We supply 4140 steel to many Fortune 500 companies. Our steel meets all their technical requirements, and they’re very happy with our service. Here’s what some of our clients say:

Michael from Global Manufacturing Inc.:

“OTAI’s 4140 steel plates are top-notch. They always meet our specs and deliver fast. No issues at all.”

Emily from Tech Gear Ltd.:

“We rely on OTAI for our 4140 steel needs. Their custom sizes are perfect, and the packaging is great. Highly recommend them!”

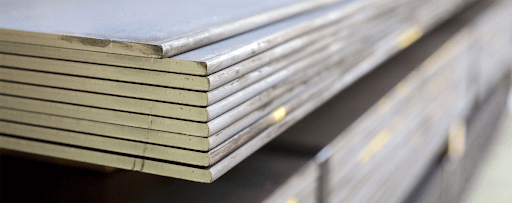

Common Uses of 4140 Steel Plates

4140 steel plates are used in many industries. Some common uses include:

- Automotive: Great for gears, shafts, and other parts.

- Oil and Gas: Perfect for drilling equipment and pipelines.

- Machinery: Ideal for molds, dies, and machine parts.

How to Order from OTAI

Ordering from OTAI is easy. Here’s how:

- Contact Us: Tell us what you need.

- Get a Quote: We’ll give you a good price.

- Place Your Order: Confirm your order, and we’ll handle the rest.

- Fast Delivery: Get your 4140 steel plates quickly.

Why Trust OTAI?

OTAI is your best choice because:

- Experienced Team: We know steel inside and out.

- Customer First: We put your needs first.

- Worldwide Supply: We deliver to customers all over the world.

Why 4140 Steel Plate Hardness Matters

The hardness of 4140 steel plates makes them a great choice for many applications. At OTAI, we provide high-quality 4140 steel with benefits like always having stock, great packaging, and trust from big companies. Contact us today to learn more or place your order.

Ready to order or have questions? Contact OTAI now, and let us help you with your 4140 steel plate needs.

Understanding 4140 Steel Plate Price: A Buyer’s Guide

Understanding 4140 Steel Plate Price: A Buyer’s Guide