4140 Annealed Plate: Precision Engineering for Diverse Industries

4140 Annealed Plate: Precision Engineering for Diverse Industries

In the dynamic realm of engineering and manufacturing, the search for materials combining strength, toughness, and ductility is ceaseless. The 4140 Annealed Plate emerges as a versatile and dependable option, pivotal across diverse industries. At OTAI, our dedication to superior quality is evident in every 4140 Annealed Plate we offer—more than mere components, they form the cornerstone of your projects.

Unveiling the Potential of 4140 Steel through Annealing

Annealing is a transformative process for 4140 steel, unlocking its full capabilities. Through precise heating and cooling, internal stresses are alleviated, yielding a uniform microstructure. This meticulous treatment enhances ductility and facilitates precision machining, making our 4140 Annealed Plates the preferred choice.

Versatility and Precision: The Role of 4140 Annealed Plate

The 4140 Annealed Plate epitomizes versatility, serving crucial roles across a spectrum of demanding applications. From intricate automotive gears to aerospace essentials, our plates deliver consistent performance. Detailed case studies underscore its resilience and reliability under exacting conditions.

Available and Adaptable: Accessibility and Customization at OTAI

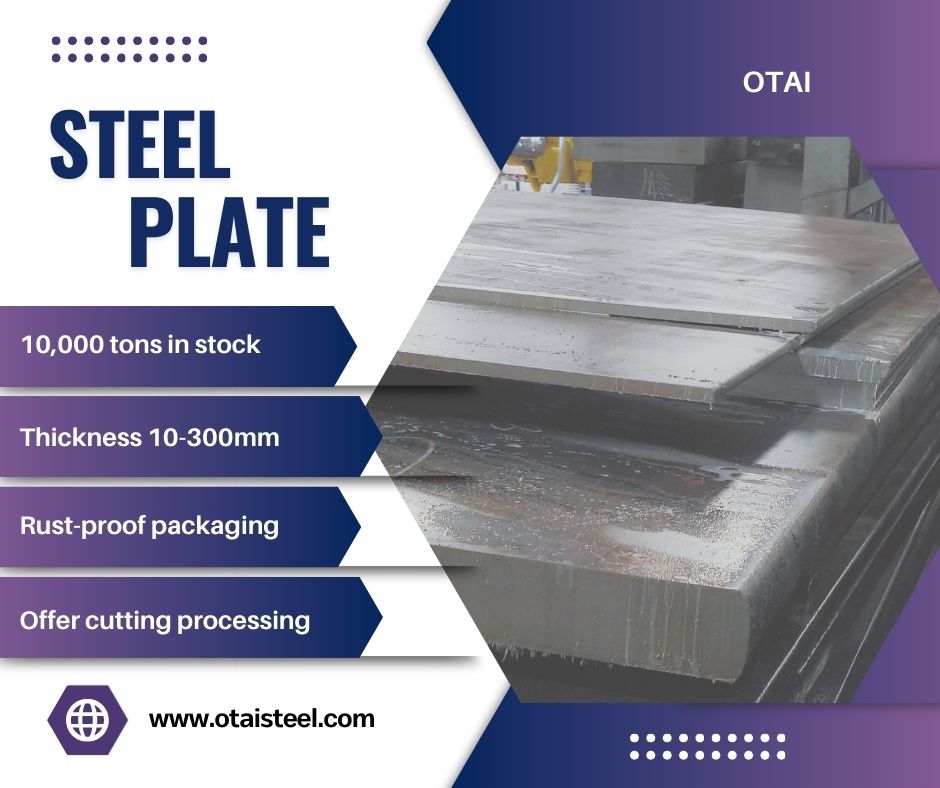

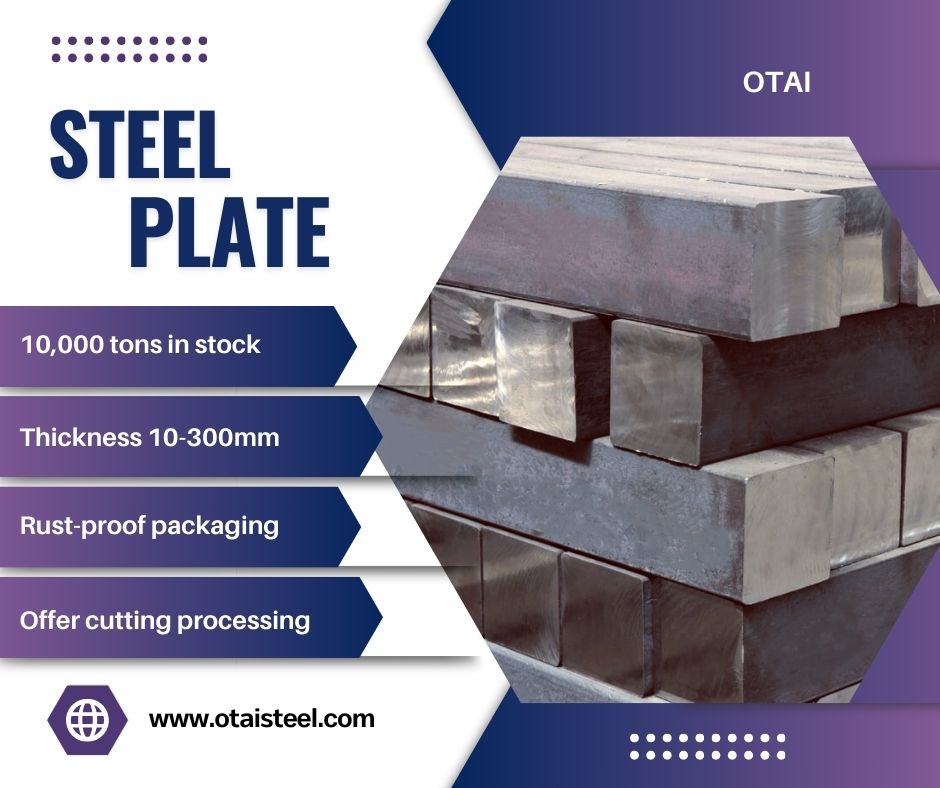

Accessibility and customization are pivotal at OTAI, catering to dynamic client needs. Our 10,000 tons of inventory ensures swift availability of 4140 Annealed Plates in various sizes and specifications. Tailored cutting and packaging services further accommodate specialized requirements, aligning each order with your project’s unique demands.

Commitment to Quality: Ensuring Consistency and Compliance

Quality defines our ethos at OTAI. Rigorous quality controls uphold international standards, ensuring every 4140 Annealed Plate meets stringent criteria.

Innovation and Progress: OTAI’s Forward-Thinking Approach

Our inventory reflects more than materials—it mirrors our commitment to progress. Continual updates integrate cutting-edge steel technology, ensuring our clients benefit from the latest innovations. Our team pioneers new applications and enhancements for the 4140 Annealed Plate, staying ahead of industry trends.

Customer-Centric Excellence: Our Guiding Philosophy

At OTAI, customer satisfaction is paramount. We foster partnerships built on trust, reliability, and exceptional service. Our dedicated customer support team provides comprehensive assistance throughout your project journey, ensuring a seamless experience with OTAI.

Raising Standards: Partner with OTAI for Your 4140 Annealed Plates Needs

In summary, the 4140 steel Plate exemplifies our unwavering pursuit of excellence. Whether you seek standard offerings or bespoke solutions, OTAI stands ready as your trusted ally in achieving perfection. Contact us today to discover how our 4140 Annealed Plates can elevate your projects and contribute to your success story.

The Ultimate Guide to AISI H13 Steel Equivalents

The Ultimate Guide to AISI H13 Steel Equivalents From Specification to Solution: The Importance of 4140 Plate Thickness

From Specification to Solution: The Importance of 4140 Plate Thickness Exploring 4140 Alloy Steel Plates Hardness

Exploring 4140 Alloy Steel Plates Hardness Enhancing Performance with 4140 HT Steel Plate

Enhancing Performance with 4140 HT Steel Plate Factors Influencing 4140 Steel Plate Prices

Factors Influencing 4140 Steel Plate Prices 4140 steel plate properties-Understanding AISI 4140

4140 steel plate properties-Understanding AISI 4140 4140 HR alloy steel plate-Unleashing Industrial Potential with OTAI’s Expertise

4140 HR alloy steel plate-Unleashing Industrial Potential with OTAI’s Expertise 4140 Plate Steel Specifications: The Ultimate Guide to 4140 Alloy Steel

4140 Plate Steel Specifications: The Ultimate Guide to 4140 Alloy Steel