How to find 4140 Alloy Steel Plate Factory

How to find 4140 Alloy Steel Plate Factory

Hey there, if you’re in the market for top-notch 4140 alloy steel plates, finding a reliable supplier is key. Whether you’re a steel wholesaler or distributor, you want quality and reliability without the headache. Here’s how you can find the perfect factory for your 4140 steel needs.

Know What You Need

First things first, figure out exactly what you need. Size, quantity, any special tweaks – knowing this upfront makes your search smoother.

Finding Your Match

Start your hunt online. Look for companies with a solid rep in the steel game and experience handling 4140 alloy steel. Check out reviews and see what others are saying.

OTAI Special Steel: Your Go-To Source

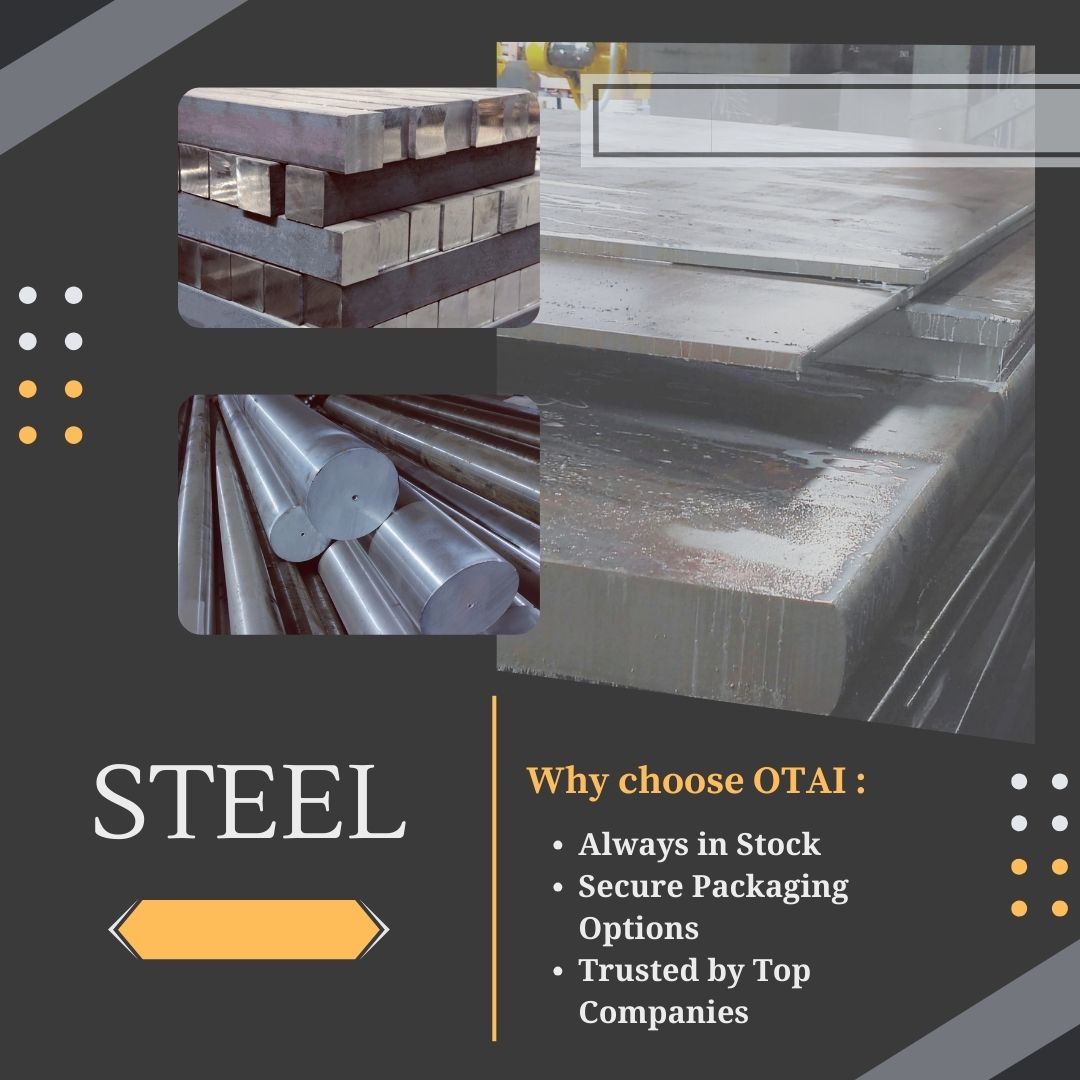

At OTAI Special Steel, we’re all about top-notch 4140 alloy steel plates. With years in the business and a reputation for quality, we’ve got your back.

Ready-to-Go Inventory and Custom Options

We keep a full stash of 4140 plates in different sizes. Need something custom? No sweat. We’re all about making it work for you and getting it done fast.

Packing and Shipping Done Right

We get it – steel needs TLC when it ships. We’ve got strapping, wooden crates, rust protection – you name it, we pack it right.

Happy Customers, Real Results

James Smith, Smith Steel Distributors

“OTAI’s been a game-changer. They deliver on time, every time, with plates that fit our specs perfectly.”

Linda Chen, Chen Industries

“We’ve trusted OTAI for years. Their reliability with large orders is why we keep coming back.”

How to find 4140 Alloy Steel Plate Factory

When you’re on the hunt for a 4140 alloy steel plate factory, stick with folks who get it done right. Look for a supplier like OTAI Special Steel – they’ve got the goods, the service, and the rep to back it up.

Want more on our 4140 alloy steel plates? Swing by our site or hit us up direct. Let OTAI take care of your steel needs – you won’t be disappointed.

SAE 4140 Hot Rolled Alloy Steel Plate Properties

SAE 4140 Hot Rolled Alloy Steel Plate Properties Steel Plate SAE 4140: Who Needs It and Why

Steel Plate SAE 4140: Who Needs It and Why Preventing Rusting of Zinc Plated 4140 Steel

Preventing Rusting of Zinc Plated 4140 Steel Hot Rolled Alloy Steel Plate 4140 for Construction

Hot Rolled Alloy Steel Plate 4140 for Construction Why Choose Alloy Steel Plate 4140 for Manufacturing

Why Choose Alloy Steel Plate 4140 for Manufacturing Why Choose 4140 Steel Plate in the UK?

Why Choose 4140 Steel Plate in the UK?

Guide to Using 3 8 Steel Plate 4140 in Projects

Guide to Using 3 8 Steel Plate 4140 in Projects