In the realm of precision molding, the choice of steel can make a significant difference. 1.2311 steel, a pre-hardened chromium-molybdenum alloyed tool steel, emerges as a versatile option. This guide not only explores the technical details of 1.2311 steel but also outlines the essential qualities to seek in a premier 1.2311 steel supplier.

In the realm of precision molding, the choice of steel can make a significant difference. 1.2311 steel, a pre-hardened chromium-molybdenum alloyed tool steel, emerges as a versatile option. This guide not only explores the technical details of 1.2311 steel but also outlines the essential qualities to seek in a premier 1.2311 steel supplier.

Precision in Every Mold: Understanding 1.2311 Steel

1.2311 steel is widely recognized for its versatility and finds extensive use in various applications, particularly in precision molding. Let’s delve into its key attributes:

| Chemical Composition | |

|---|---|

| C | 0.28-0.40% |

| Si | 0.20-0.80% |

| Mn | 0.60-1.00% |

| P | ≤ 0.030% |

| S | ≤ 0.030% |

| Cr | 1.80-2.10% |

| Mo | 0.15-0.25% |

Mechanical Properties:

- Hardness: 280-325 HB

- Tensile Strength: 1000-1250 MPa

- Impact Toughness: ≥ 20 J

Applications of 1.2311 Steel:

- Injection molds for high-performance plastics

- Extrusion dies

- Structural components in the automotive industry

Choosing Excellence: Qualities of a Premier 1.2311 Steel Supplier

1. Proven Expertise: Opt for a supplier with a track record in handling and supplying 1.2311 steel. Experience in the nuances of this steel ensures reliability and quality in every batch.

2. Comprehensive Product Range: A top-notch supplier offers an extensive range of 1.2311 steel forms – round bars, flat bars, and plates, providing flexibility in meeting diverse manufacturing needs.

3. Quality Certifications: Ensure your supplier adheres to industry standards with certifications like ISO 9001:2015. A commitment to quality management guarantees the consistency of the supplied 1.2311 steel.

3. Quality Certifications: Ensure your supplier adheres to industry standards with certifications like ISO 9001:2015. A commitment to quality management guarantees the consistency of the supplied 1.2311 steel.

4. Customization Capabilities: The ability to provide tailored solutions reflects a supplier’s commitment to meeting specific client requirements. Look for a supplier capable of offering customized dimensions and treatments.

5. Timely Deliveries: In the fast-paced manufacturing industry, on-time delivery is paramount. Choose a supplier with a reputation for prompt and reliable deliveries to keep your production schedules intact.

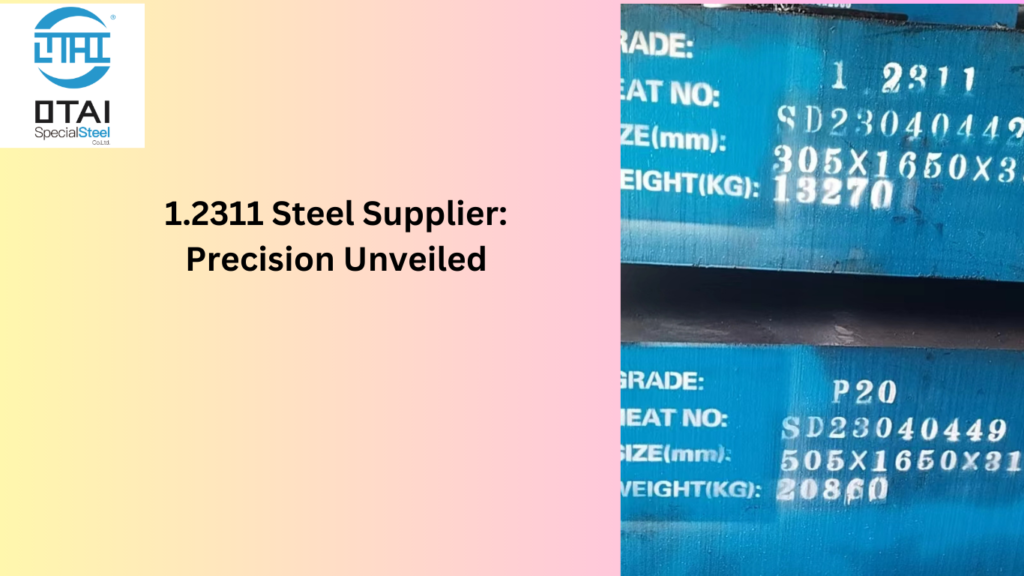

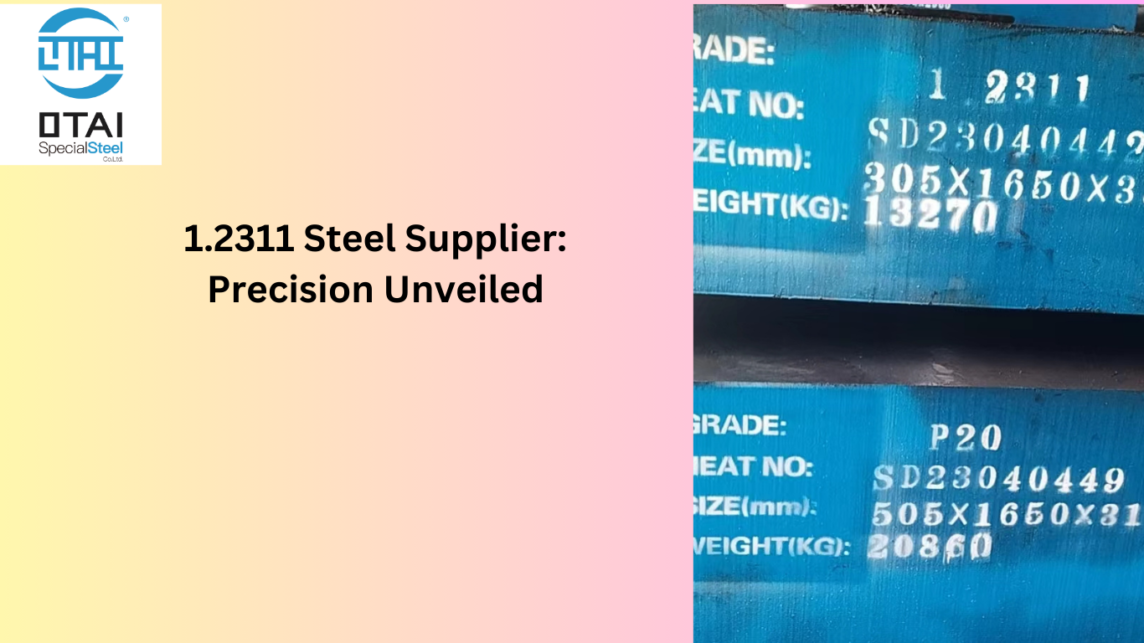

OTAI’s Advantages: A Cut Above the Rest

– Diverse Product Range:

OTAI stands out with a wide array of 1.2311 steel products, ensuring you have choices that perfectly fit your manufacturing needs.

– ISO Certification:

We proudly possess ISO certification, underlining our commitment to maintaining high-quality standards in our 1.2311 steel supply.

– Swift Deliveries:

At OTAI, we understand the value of time in your production process. Our swift delivery services ensure that your steel requirements are met promptly, enhancing your manufacturing efficiency.

Conclusion: Elevating Precision with 1.2311 Steel

As you explore the realm of precision molding, partnering with a superior 1.2311 steel supplier is a strategic move. The combination of technical expertise, product quality, and reliable deliveries ensures a seamless production process, bringing precision and excellence to every mold.

When seeking the ideal 1.2311 steel supplier, consider these aspects to forge a partnership that enhances your manufacturing capabilities and elevates your end products.

Embark on a transformative journey into the heart of precision molding with the prowess of 1.2311 steel suppliers, the architects of innovation and reliability.

Embark on a transformative journey into the heart of precision molding with the prowess of 1.2311 steel suppliers, the architects of innovation and reliability.