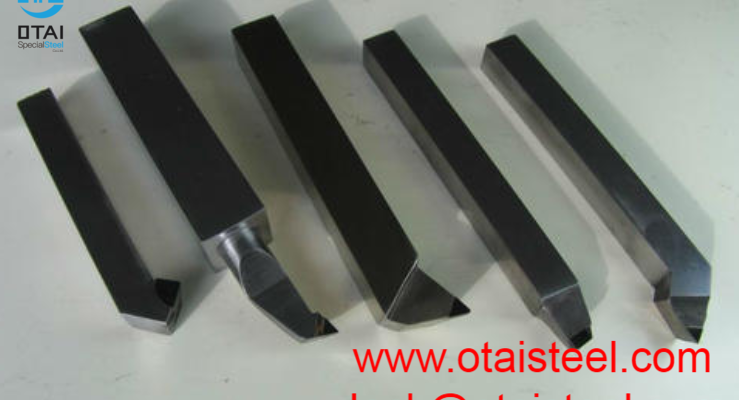

High speed steel is divided into Melting high speed steel and powder metallurgy high speed steel.

Powder High Speed Steel (powder treated steel) is one of high speed steel,which produced by high pressure argon or pure Nitrogen atomized molten process.

Advantages of Powder High Speed Steel :

(1) With well and uniform crystalline structure can be obtained.It has good mechanical properties.

The carbide distribution is more uniform, resulting in stronger strength and toughness, and greater variable opening force.

(2) With better grinding property than general high speed steel ,

It can help to improve the grinding efficiency while it processing as tools , and it will have a well grinding surface for cutting item.

(3) Decresing the deformation as quenching heat treatment process .

(4) The wear resistance more 20%-30% than general high speed steel .

(5) High qualified production rate of hot-forming .

Application:

Suitable for manufacturing cutting tools and large size tools (such as: hob, gear shaper, etc.), It is also suitable for manufacturing precision tools and complex tools which with large grinding capacity, and use in those tools (continuous cutting tools) used under high pressure dynamic load.

Powder high speed steel, It make up for the common high speed steel inherent defects because of the the good structure uniformity and carbide segregation characteristics, , and improve High speed steel quality and performance .

Ms Elwa Lee

Mobile/WhatsApp: 0086-15899675236

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Elwa@otaisteel.com