AISI H13 belongs to hot work mold steel, which is mainly used for die-casting mold, extrusion mold, wear-resistant plastic mold.

What is the AISI H13? The customer who produced the die-casting mold asked me that he had previously purchased AISI H13 from other supplier to produce aluminum alloy die-casting molds, and sometimes cracks occurred at 3000 molds, and 20,000 cracks were scrapped. And what happened on the H13? Where it should be applied on?

The huge price difference range on AISI H13 mold steel makes the purchasers confusion on the price and quality in such mixed market. How to distinguish the H13 mold steel from the different quality grade?

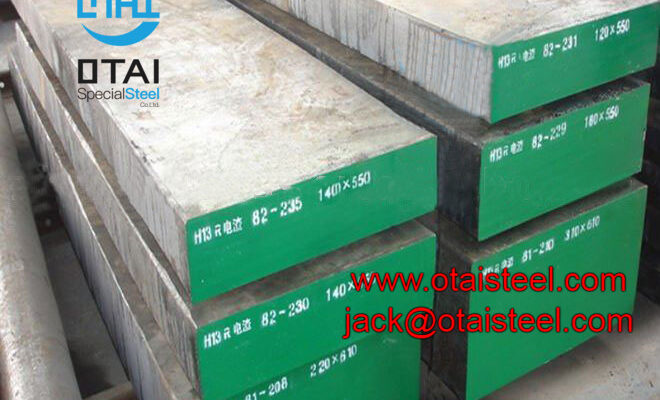

1) Non-standard H13 mold steel made by the small private company

2) National standard H13 die steel made by the small private company

3) ESR H13 mold steel made by the small private company

4) National standard H13 die steel

5) ESR H13 mold steel

6) ESR + ultra-refined H13 mold steel;

7) Atmosphere protection ESR H13 mold steel;

Steel alloys made from iron ore steel have less impurities. Advanced steelmaking equipment can effectively remove impurities. The steelmaking process has many steps and rigorous, which can ensure the stability of the mold steel quality. The steel mills that can meet these conditions are all large state-owned steel mills. The corresponding AISI H13 tool steel grades are on grade 4, 5, 6, and 7. These grades quality mold steel has high price, stable quality and long mold life.

Consequently, it is extremely important for selecting the most reliable supplier instead of focusing on the price. Our OTAI is very proud on this special steel field. As we are with the open and sincere attitudes on the cooperation. We provide the obtainable, affordable and the most important- reliable tool steel for our dear customers everywhere. That is why we got the firm and loyal trust from all the customers.

Ms Phoenix Li

Mobile/WhatsApp: 0086-13925830813

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Phoenix@otaisteel.com