38CrMoAl is a nitrided Alloy Steel with high wear resistance, high fatigue strength and high strength.

It is mainly used for nitrided parts with precise dimensions after heat treatment, or various nitrided parts with low impact load and high wear resistance. Such as boring bar, grinding machine spindle, automatic lathe spindle, worm, precision screw, precision gear. And also such as High-pressure valves, valve stems, gauges, templates, rollers, replicas, cylinder blocks, compressor piston rods, governors on steam turbines, rotating sleeves, fixing sleeves, various wear-resistant parts on rubber and plastic extruders, etc.

We dealed with a 38CrMoAl Alloy Steel project before with a middle east customer .

Order confirm of 38CrMoAl Alloy Steel round bar

Customer need 26 tons 1.8509 alloy steel, Otai Steel engineer suggest 38CrMoAl to them .There is rare 1.8509 stock material in China ,all of Chinese steel mill production 38CrMoAl instead of 1.8509.

Customer try to order 1.8550 /1.8507 /1.8519 instead of 1.8509 alloy steel round bar .and our engineer update the folow chemical composition as below to customer for reference . and customer Choose 38CrMoAl finally .

| Grade | Item | C % | Si % | Mn % | P % | S % | Cr % | Mo % | Al % | Ni % | V % |

| 1.8509 | Round Bar | 0.38-0.45 | 0.20-0.40 | 0.40-0.70 | ≤0.025 | ≤0.035 | 1.50-1.80 | 0.20-0.35 | 0.80-1.20 | * | * |

| 38CrMoAl | Round Bar | 0.35-0.42 | 0.20-0.45 | 0.30-0.60 | ≤0.025 | ≤0.035 | 1.35-1.65 | 0.15-0.25 | 0.70-1.10 | * | * |

| 1.8550 | Round Bar | 0.30-0.38 | ≤0.40 | 0.40-0.70 | ≤0.025 | ≤0.035 | 1.50-1.80 | 0.15-0.25 | 0.8-1.20 | 0.85-1.15 | * |

| 1.8507 | Round Bar | 0.30-0.37 | ≤0.40 | 0.40-0.70 | ≤0.025 | ≤0.035 | 1.0-1.13 | 0.15-0.25 | 0.8-1.2 | * | 0.1-0.2 |

| 1.8519 | Round Bar | 0.27-0.34 | ≤0.40 | 0.40-0.70 | ≤0.025 | ≤0.035 | 2.3-2.7 | 0.15-0.25 | * | * | * |

The order delivery condition as follow :

–1.Hot Rolled;;Black Surface

–2.Hardness:160~260HB

–3.Length:4000~6000mm

–4.UT-SEP 1921C/C or Better

–5.Chmical Analyzed 38CrMoAl ( or 1.8509 )

–6.Fix Diameter ( Accept the tolerance -/+1.5mm)

–7.SGS or other third party inspection under buyer‘s arrangement

Order inspector of 38CrMoAl Alloy Steel Round bar .

After our QC feedback for the test process of inspector,the inspector did not do the steel test before ,and there without some mistake of the test way .

1.First ,the goods is Hot Rolled,Black Surface ,and there is reasonable with rusted ,Black sueface means the item is Ex-mill condition cover with Oxide Layer.

2.About the unit weight and Label “38CrMoALA”, each of the sizes produced in a factory and aligned with the printed label.

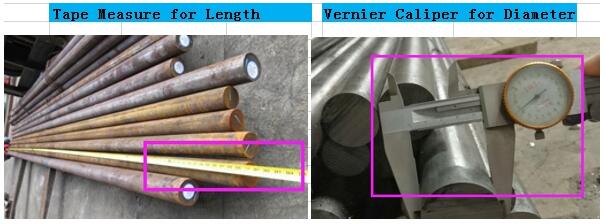

3.About the Diameter ,The inspector did not use the Vernier Caliper to check it. AGS is the first one who use the length ruler to check it.

After the long meeting with customer , they agree our test report instead of AGS .and finished 38CrMoAl Alloy Steel round bar shipment and payment process as usually .

Ms Elwa Lee

Mobile/WhatsApp: 0086-15899675236

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Elwa@otaisteel.com