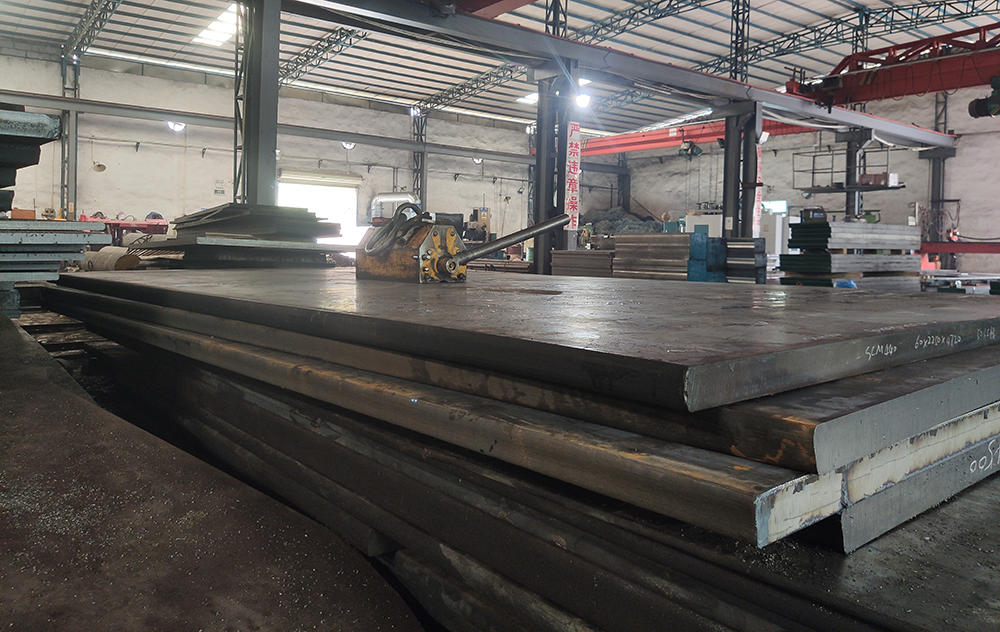

SCM440 steel china supplier and stock factory, Otai Special Steel supply in SCM440 round bar, plate, flat, hexagonal bar. SCM440 is a Chrome alloy structure steel, It contains 0.9-1.2% Cr, usual use in gears, pump shafts and tool holders. Delivery condition of 18-22HRc.

If you have any enquiry, welcome you contact our sale team by email or telephone.

1.Chemical composition of JIS alloy SCM440

| JIS | C | Si | Mn | Cr | Mo | P | S |

| SCM440 | 0.38~0.43 | 0.15~0.35 | 0.60~0.85 | 0.90~1.20 | 0.15~0.30 | ≤0.030 | ≤0.030 |

2.Supply of JIS SCM440

Otai Special Steel supply SCM440 steel plate, round bar, flat bar, square, hexagonal bar. Details size range as below:

- SCM440 steel plate: thickness 2mm to 1500mm x width 200mm to 3000mm

- SCM440 Steel round: Ø5mm to Ø3000mm

- SCM440 flat bar: 5mm-200mm x 10mm -300mm

- SCM440 hexagonal: hex 5mm to 110mm

3.JIS SCM440 equivalent

| ASTM A29/29M | C | Si | Mn | Cr | Mo | P | S |

| 4140 | 0.38~0.43 | 0.15~0.35 | 0.75~1.00 | 0.80~1.10 | 0.15~0.25 | ≤0.035 | ≤0.040 |

| DIN WN-r | C | Si | Mn | Cr | Mo | P | S |

| 1.7225 | 0.38~0.45 | ≤0.40 | 0.60~0.90 | 0.90~1.20 | 0.15~0.30 | ≤0.035 | ≤0.035 |

| GB/T | C | Si | Mn | Cr | Mo | P | S |

| 42CrMo4 | 0.38~0.45 | ≤0.40 | 0.60~0.90 | 0.90~1.20 | 0.15~0.30 | ≤0.035 | ≤0.035 |

4.Application of Alloy Steel JIS SCM440

JIS SCM440 is commonly used in oil and gas sector. Typical applications as Connecting rod, Pin seam jacketed conveyor, gears, stem assembly, pump shaft and the tool holder.

5.Forging of JIS SCM440 steel alloy material

At 1200°C start forging, keep the forging temperature no below 850°C

6.Annealing of SCM440 alloy steel material

Heat to 850°C slowly, ensure heat thoroughly. Then cool in the furnace.

7.Quenching for Steel JIS SCM440

SCM440 steel usually supply at 18-22HRc, if need Hardening. Heat SCM440 to 840-870°C,then quench in oil until to room temperature.

8.Tempering to JIS SCM440 alloy steel material

Heat SCM440 steel to suitable Tempering temperature, Tempering temperature between 250-375°C.

9.Heat treatment of JIS SCM440 alloy steel grade material

According different use requirement, SCM440 heat treatment is different. We advice you contact your heat treatment supplier get more details data.

10.Physical properties of JIS SCM440 steel

- Density of SCM440: 7.85 kg/cm3

- Thermal expansion co-efficient: 12.2 µm/m°C at 0-100°C

- Thermal conductivity: 42.6 W/mK @100°C.

11.Mechanical properties of Alloy Steel JIS SCM440

- Tensile: 100-130 KSI

- 0.2% Proof stress: 80-110 KSI

- Elongation: 20%

- Reduction of Area: 40% Min

- hardness: 18-22HRc / 217-235 HBS

*All test at room temperature 25°C and heat treatment SCM440 steel to 18-22HRc.

12.Quality Assured and Certification of SCM440 material

All SCM440 Steel quality by our ISO 9001:2008 quality management system. Material MTC Certification follows to order delivery to Customers.

Contact us now, Free sample waiting for you!

Email: Jack@otaisteel.com

Tel: +86-769- 23190193

Fax: +86-769-88705839