1.2367 Hot Work Tool Steel

OTAI SPECIAL STEEL is 1.2367 tool steel stockholders and suppliers from china. more than 25 years of experience in 1.2367 tool steel round bar, flat bar, and plate supply.

1.2367 steel is chromium-Molybdenum hot work steel similar to H11 hot work steel, but contains a higher molybdenum content. The higher molybdenum gives it better hot hardness and temper resistance, along with higher attainable hardness and deeper hardenability than the more common H11 and H13 hot work steels.

Typical applications include extrusion tooling, hot forging dies, hot heading dies, hot shear blades, hot punches, and mandrels. Also, it can be used for hot grippers die and die casting tooling for copper and brass.

1.2367 hot work tool steel properties are as below:

Form of Supply

1.2367 Hot Work Tool Steel, we can supply the round bar, flat bar, plate, hexagonal steel bar, and steel square block. 1.2367 steel Round bar can be sawn to your required lengths as one-offs or multiple-cut pieces. 1.2367 Rectangular steel pieces can be sawn from flat bars or plates to your specific sizes. Ground tool steel bar can be supplied, providing a quality precision finished bar to tight tolerances.

- Round

- sheet

- Square

- Plate

Chemical composition

| C | Si | Mn | S | P | Cr | Mo | V |

| 0.35-0.4 | 0.3-0.5 | 0.3-0.5 | Max 0.03 | Max 0.03 | 4.8-5.2 | 2.7-3.2 | 0.4-0.6 |

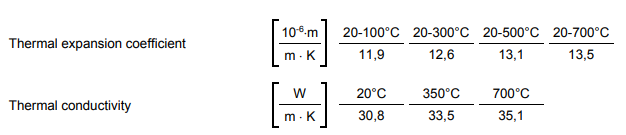

Physical Properties

Heat treating instructions

Critical temperatures

Ae1: 850℃ Ar1: 853℃

Hardening:

Preheating: To Minimize distortion in complex tools use a double preheat:621-677℃, equalize, then raise to 760-816℃ and equalize, for normal tools, use only the second temperature range as a single preheating treatment. Austenitizing(High Heat): heat rapidly from the preheat. Furnace or salt:1024-1080℃ for maximum toughness, use 1024-1038℃. For maximum hot hardness and heat checking resistance use 1066-1080℃

Quenching: Air, pressurized gas, warm oil or salt,

For Pressurized gas, a minimum quench rate of approximately 28℃, per minute to below 538℃ is required to obtain the optimu properties in the steel.

For oil, quench until black, about 482℃, then cool in still air to 66-51℃.

For salt maintained at 538-593℃, equalize in the salt, then cool in still air to 66-51℃,

Tempering:

Temper immediately after quenching, Typical temperature range is 538-593℃, do not temper below 538℃, hold at temperature for 2 hours then air cool to ambient temperature, double tempering is required

Annealing:

Annealing must be performed after hot working and before rehardening.

Heat at a rate not exceeding 222℃ per hour to 732-788℃, and hold at temperature for 1 hour per inch of maximum thickness,2 hours minimum, then cool slowly with the furnace at a rate not exceeding 28℃ per hour to 538℃. continue cooling to ambient temperature in the furnace or in the air, the resultant hardness should be a maximum of 235HBW.

Quality Assured Supply

1.2367 tool steel is supplied in accordance with our ISO 9001 : 2008 registration.

Contact our experienced sales team to help you with your 1.2367 tool steel questions inquiry by Email or Telephone. The questions will be replied to in 24 hours.

Email: jack@otaisteel.com

Tel: +86 769 2319 0193

Fax: +86 769 8870 5839