Hot Work Tool Steel

Our hot work tool steel is a uniquely processed group of steel used to shape and cut other materials at high temperature. Classified with the ‘H’ prefix, ‘H-group’ steels undergo intense processing to allow them to retain strength and hardness whilst being used in high temperature conditions.

The characteristic hardness and resistance of our hot work tool steel is due to high level of carbide, moderate level of alloy and low level of carbon.

Our H1 – H19 steels contain approx. 5% chromium, H20 – H39 contain approx. 10-18% tungsten and 3-4% chromium, and our H40 – H59 steels are based on molybdenum.

H-11 Tool Steel

H-11 Tool Steel is a chromium, molybdenum, vanadium hot work tool steel that is known for its high hardenability and excellent toughness. have 0.3-0.6% Vanadium.

H-13 Tool Steel

H-13 Tool Steel is a chromium, molybdenum, vanadium hot work tool steel that is known for its high hardenability and excellent toughness.

SKD61 Tool Steel

SKD61 Tool Steel is a high-carbon high-chromium alloy tool steel.

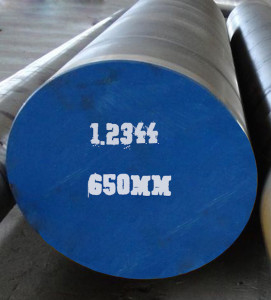

1.2344 Tool Steel

1.2344 Tool Steel is comprised of chrome, molybdenum, vanadium and silicon.

X40CrMoV5-1 Tool Steel

The X40CrMoV5-1 steel is a hot work tool Steel, It belong to NF A 35-590-1992 standard.

It is equivalent with H13 tool steel,1.2344 hot work steel, SKD61 special steel, BH13 steel, 4Cr5MoSiV1 special tool steel.