DC53 Tool Steel

JIS DC53 tool steel china supplier and stockholders, Otai special Steel are Special steel china suppliers of DC53 steel in round bar, flat bar, sheet , plate and steel block. we can saw cutting DC53 as your requirements size. DC53 is improved new type of cold work die steel from SKD11 . The technical specification in Japanese industrial standard JIS G4404.

Cold work DC53 tool steel overcomes the insufficient of SKD11 high temperature tempering hardness and toughness of weakness, DC53 tool steel will fully replace SKD11 tool steel in the field of general and precision mould . Its toughness is 2 times of SKD11, DC53 toughness is more prominent in the cold work die. Made of DC53 tools steel rarely appear crack and craze, greatly improving the service life.

The DC53 tool steel has a uniform distribution of fine carbides. It has great galling and wear and fatigue resistance. It has also a High temper resistance to support PVD & nitride surface treatments. And it has Machining and grinding properties are superior to most other tool steels.

Related Specifications JIS G4401 (2000) DC53 tool steel

DC53 steel Form of Chemical composition

| C(%) | Si(%) | Mn(%) | Cr(%) | Mo(%) | V(%) |

| 0.95 | 1.00 | 0.40 | 8.00 | 2.00 | 0.30 |

DC53 Form of Supply

For Cold work tool steel DC53, we can supply the steel round bar, steel flat bar, steel sheet, plate and square block. DC53 tool steel round bar can be sawn to your required length and size. Rectangular steel pieces can be sawn from flat bar or plate to your specific sizes. Ground tool steel bar can be supplied, providing a quality precision finished bar to tight tolerances.

- Round

- sheet

- Plate

- Square

DC53 steel Applications

The Cold work DC53 Tool Steel is found in Punches & dies, Draw & forum dies, Shear blades, Shredder knives, Thread & form rolls, Cold heading dies and Mill rolls & slitters.

Heat treatment JIS DC53 steel

The DC53 Tool steel heat treatment process can be broken down into 4 segments, Hardening (quench) & Tempering.Annealing & Normalized.

Most customers only need make the Hardening (quench) & Tempering for DC53 steel aplication.

- DC53 tool steel heat treatment

JIS DC53 tool steel Forging

Slowly and uniformly Heat the DC53 tool steel to 700°C (1292°F),then rapidly heat the DC53 steel to 900-1040°C(1652-1904°F). After forging slowly cool down.

DC53 tool steel Hardening | quenching

Heat slowly the DC53 tool steel to 850°C(1562°F), Soak thoroughly at the temperature. the brought up to 1030°C(1886°F)oil quenching or air cool.

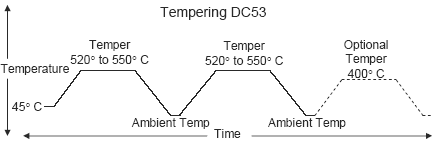

Tool steel DC53 Tempering

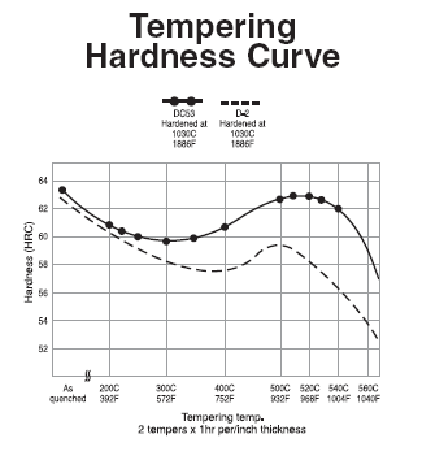

Commonly performed DC53 Tempering is in a high Vacuum controlled convection furnace. The temper is perfect after Hardening. conducted as soon as the part can be hand at about 45° C (120° F) to 65° C (150° F). by High temperature tempering and hardening, hardness tool steel DC53 can reached 65 HRC MAX. common application ,we advice the Hardness no higher than 62HRC. DC53 steel DC53 tool steel Tempering data only for reference as below:

DC53 tool steel Annealing

Normal D53C annealing condition delivery, hardness 255HB MAX. When finished the DC53 Steel tool, then can heat treatment to appropriate hardness.

Regular size and Tolerance

| 1) Hot Rolled round bar | |||

| Diameter (mm) |

Diameter Tolerance (mm) |

Diameter (mm) |

Diameter Tolerance (mm) |

| 6.4~15.8 | -0.038 ~0.038 | 181~<206.2 | 0~1.6 |

| 15.8~<77.6 | 0~0.10 | 206.2~<257 | 0~2.4 |

| 77.6~<103 | 0~0.15 | 257~<307.7 | 0~3.2 |

| 103~<181 | 0~0.78 | ≥307.7 | 0~4.7 |

| 2) Hot Rolled steel plate | |||

| Thickness (mm) |

Thickness Tolerance (mm) |

Thickness (mm) |

Thickness Tolerance (mm) |

| ≤25.4 | -0.41~0.79 | >127~152 | -1.60~2.39 |

| >25.4~76 | -0.79~1.19 | >178~254 | -1.98~3.18 |

| >76~127 | -1.19~1.60 | >254~305 | -2.39~3.96 |

Others have not specified size, pls contact our experienced sales team.

Processing

DC53 tool steel round bar and flat sections can be cut to your required sizes. Ground steel bar can also be supplied, providing a high quality tool steel precision ground tool steel bar to your required tolerances. DC53 Tool Steel is also available as Ground Flat Stock / Gauge Plate, in standard and nonstandard sizes.

Contact our experienced sales team to help you with your DC53 questions

by email or telphone. The questions will be reply in 24 hours.