EN19 steel is alloy structural steel. It is the most widely used high-strength steel in the automotive field. It applys on the gears and engine structures, crankshafts, knuckles, connecting rods, main shafts, intermediate gears.

OTAI has our own Chemical Spectrometer for testing EN19 chemical composition

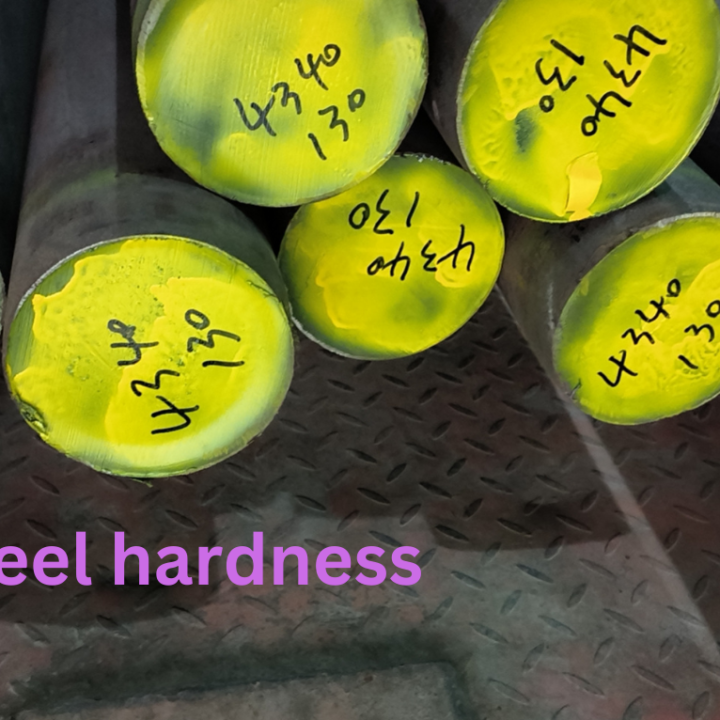

OTAI have Chemical Spectrometer for testing the EN19 chemical composition, Ultrasonic Tester and hardness tester. OTAI supply the one stop solution for the steel material. We have our own warehouse, our machine equipment: CNC flame cutting machine, Horizontal Saw and Vertical saw cutting machine, Grinding machine and Milling machine.

What is the EN grades steel material? The EN range of steel specification was first introduced in 1941 as the War Emergency, British Standard Schedule BS970. With the assistance of the Technical Advisory Committee of the Special & Alloy Steels Committee the British Standards Institute published 58 specifications (EN1 to EN58). These steels covered the different types including carbon steels, alloy steels, case hardening steels, spring steels and stainless steels. The grades were arranged sequentially according to the chemical composition, starting with low carbon grades EN1, EN2 and EN3 working up to stainless steel grades EN56, EN57 and EN58.

EN19 chemical composition is as following:

C: 0.36-0.44; Si: 0.15-0.35; Mn: 0.70-1.00; P: ≤0.040; S: ≤0.050; Cr: 0.90-1.20; Mo: 0.25-0.35.

For the equivalent material close to EN19 chemical composition, there are GB 42CrMo, DIN 42CrMo4, AISI 4140, JIS SCM440.

OTAI provided EN19 steel is produced by the only one set of imported steelmaking equipment in China. And our OTAI survive for the honest and quality, that is why we are professional on this special steel field for more than 20years. We exported the special steel to more than 30 countries all over the world, and they are passed the standard of America, Germany and Japan.