According to the life of the mold into five grades, the requirements of mold steel:

Generally, the mold is divided into five grades according to the length of service life.

Level NO1:more than a million times,

level NO2:is 500,000 to 1 million times,

level NO3:is 300,000 to 500,000 times,

level NO4: is 100,000 to 300,000 times, and level 5 is less than 100,000 times.

The first and second grade molds are required to use heat treatment

Hardness in HRC50 or so of steel, otherwise it is easy to wear, the injection of the product is prone to out of tolerance, so the selected steel should have good heat treatment performance, and in the state of high hardness has good cutting performance, of course, there are other considerations.

Usually choose Sweden’s die steel

(1)

8407, S136, the United States of mold steel 420, H13, Europe’s 2316, 2344, 083, or Japan’s SKD61, DC53 (the original metal mold material, special circumstances use).

(2)

Strong corrosive plastic generally choose S136, 2316, 420 and other steel, weak corrosive in addition to mold steel S136, 1.2316, 420, and JIS SKD61, NAK80, PAK90.

Product appearance requirements

(1)

It also have a great impact on the choice of mold materials, transparent parts and surface requirements mirror products, materials available are S136, 2316, NAK80, PAK90, 420, the transparency of the mold should be selected S136, followed by 420.

(2)

There are many pre-hard materials for the three-stage mold,mold steel grades are S136H, 2316H, 083H, and the hardness is HB270-340.

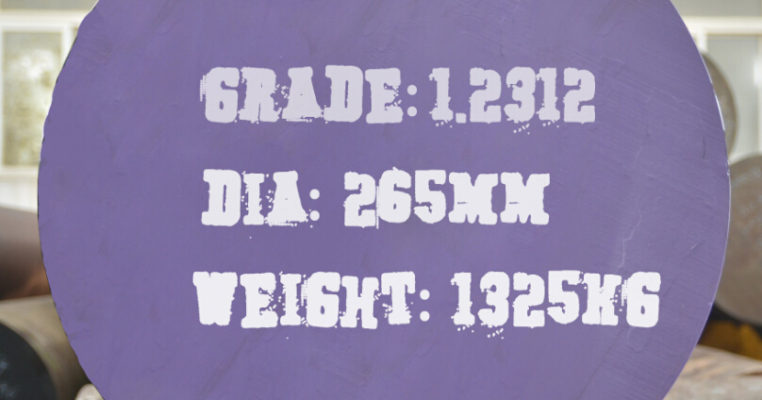

Mold steel

P20, OT718, 738, OT618, 2311, 2312, 2711 are used for grade 4 and grade 5 molds. For the molds with extremely low requirements, S50C and S45C steel may be used, which is to directly make a cavity on the mould blank.

If you want to know more or any suggestion,please conract me,let’s discuss more.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com