Basic information of M2

M2 steel is Tungsten-Molybdenum high-speed steel, which has the advantages of small carbide non-uniformity and high toughness. It is easy to overheat, so the quenching heating temperature should be strictly controlled, and the heat treatment protection requirements are strict. Due to its hardness and wear resistance, it is often used. For the manufacture of cutting tools that are difficult to cut materials. m2 steel has a large tendency to carbide, so the heat treatment protection requirements are strict, suitable for the mold to withstand shock and impact loads.

Worldwide, The M2 type is by far the most popular high speed steel having replaced T1 high speed in most applications because of its superior properties and relative economy. Typical applications for M2 high speed steel include twist drills, taps, milling cutters, Reamers, Broaches, saws, and knives.

Reference pictures:

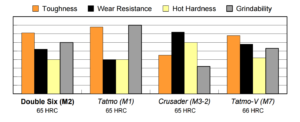

Relative properties

Physical properties:

Density:0.294lb/in3(8138kg/m3)

Specific Gravity:8.14

Modulus of elasticity:207GPa

Machinability:50-60% of a 1% carbon steel

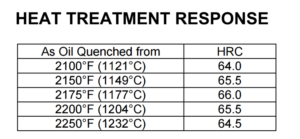

Heat treatment:

A: Hardening:

Critical Temperatures:

Ac1:1530F(832 ℃) Ac3:877℃

Ar1:777 ℃ Ar3:749℃

Preheating:To Minimize distortion and stresses in large or complex tools use a double preheat.Heat at a rate not exceeding 222℃ per hour to 593℃ equalize, then theat to 788-843℃,for normal tools, use only the second temperature range as a single preheating treatment.

Austenitizing(High heat):Heat rapidly from the preheat.

For cutting tools:

Furnace:1204-1232℃

Salt:1191-1218℃

To maximize toughness,Use the lowest temperature, To maximize hot hardness, use the highest temperature.

For punches, dies, and tools that require maximum toughness without hot hardness:

Furnace:1175-1191℃

Salt:1121-1177℃

Quenching: Pressurize gas, warm oil,or salt,

For pressurized gas, a rapid quench rate to below 538℃ is critical to obtain the desired properties.

For oil, quench until black, about 482℃, then cool in still air to 66-51℃.

For Salt maintained at 538-593℃, equalize, then cool in still air to 66-51℃.

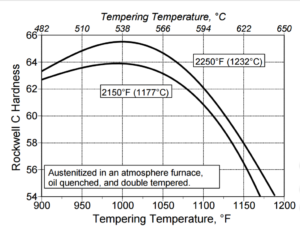

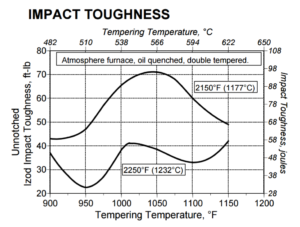

Tempering: Temper immediately after quenching,

Typical tempering range is 552-566℃, Hold at temperature for 2 hours, then air cool to ambient temperature, Doule tempering is required, for large cross sections, and especially for blanks from which tools will be cut by wire EDM, triple tempering is strongly recommended.

Annealing: Annealing must be performed after hot working and before rehardening.

Heat at a rate not exceeding 222℃ per hour to 829-843℃, and hold at temperature for 1 hourper inch of thickness,2 hours minimum, then coool slowly with the furnace at a rate not exceeding 28℃ per hour to 538℃, continue cooling to ambient temperature in the furnace or in air,The resultant hardness should be 248HBW or lower

Contact

Email: Jack@otaisteel.com

Tel: +86-769- 23190193

Fax: +86-769-88705839