High Speed Steel –M2 with good quality and high hardness

Composition and specific gravity of M2 high-speed steel

With the rapid development of science and technology, a variety of difficult-to-machine materials continue to emerge, high-performance high-speed steel and powder metallurgical high-speed steel have appeared one after another, and general-purpose high-speed steel still occupies the main position of the market. M2 high-speed steel, as a highly versatile and widely recognized mold steel material, today we will introduce the composition and proportion of M2 high-speed steel. What are the advantages and disadvantages?

Composition and specific gravity of M2 high-speed steel

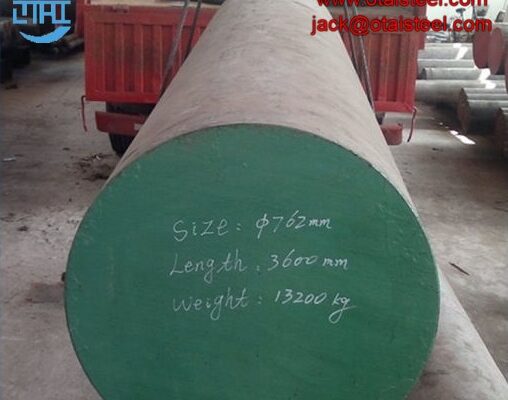

Chemical composition of M2 high speed steel: carbon C: 0.80 to 0.90, silicon Si: 0.20 to 0.45, manganese Mn: 0.15 to 0.40, sulfur S: ≤ 0.030, phosphorus P: ≤ 0.030, chromium Cr: 3.80 to 4.40, nickel Ni: ≤ 0.30, copper Cu: amount ≤ 0.25, vanadium V: 1.75 to 2.20, molybdenum Mo: 4.50 to 5.50, tungsten W: 5.50 to 6.75.

The specific gravity of M2 high-speed steel is between 8.5 and 9.0.

What are the advantages and disadvantages of M2 high speed steel?

M2 high-speed steel is a molybdenum-based high-speed steel, which has the advantages of small carbide unevenness and high toughness. Its shortcomings are prone to overheating, so the quenching heating temperature should be strictly controlled, and the heat treatment protection requirements are stricter. Because of its good hardness and wear resistance, it is mostly used to make tools for cutting difficult-to-cut materials. M2 high speed steel has a large tendency of carbides, so it has strict requirements on heat treatment protection, and is suitable for molds that can withstand shock and impact loads.

Heat treatment temperature and reference method of M2 high speed steel:

Annealing: heating to 800 ℃ ~ 850 ℃, then slowly cooling;

Quenching: heating to 1160 ℃ ~ 1220 ℃, oil quenching or hot bath;

Tempering: heating to 550 ℃ ~ 580 ℃, and then air cooling.

Main applications: cold forging dies, fine blanking dies, powder pressing dies, shearing dies, plastic dies with glass fiber, etc. Moulds suitable for shock and impact loads: deep-drawing dies, punching dies. Metal cutting saw blades, cold heading and extrusion tools.