H13 STEEL APPLICATION IN LIFE-Chapter7

authors found that an average pulse energy of 30 J mm−2 –H13 TOOL STEEL was required for continuous track deposition at pulse frequencies between 20 and 90 Hz. The melting of H13 TOOL STEEL the WC particles in the Co matrix could be controlled by changing the pulse duration. Dense and defect-free multilayer specimens of WC–17 wt.%Co cermet, with microhardness of 1250–1700 Vickers, were fabricated. Dense, crack-free, thin wall specimens of a cermet with 85%WC, 10%Co, 5% impurities were obtained by Xiong et al. (282) using the LENS process. The average hardness of the depositions was about 1300 HV. The authors observed a layered structure in their depositions, which they explained by the coalescence of H13 TOOL STEELthe WC to form large particles, but H13 TOOL STEEL subsequent studies showed that they are due to the formation and remelting of a H13 TOOL STEEL low temperature eutectic in the underlying material (283). Therefore,H13 TOOL STEEL to avoid remelting and the resulting inhomogeneity in the microstructure, the temperature in the layer immediately below that being deposited must remain below the eutectic temperature. The influence of the processing parameters on the microstructure, mechanical properties and wear resistance of WC–12%Co cermets laser-deposited by the LENS process were studied by Balla et al. (284). The results showed that carbide dissolution and carbide particle distribution must be controlled by proper selection of the laser parameters in particular of the laser beam energy. H13 TOOL STEELCoatings produced at 365 and 465 J mm3 presented a hardness of about 1180 HV, H13 TOOL STEEL and a very high dry sliding wear resistance against an Si3N4 counterbody (specific wear rate ∼10−6 mm3 Nm−1).H13 TOOL STEEL

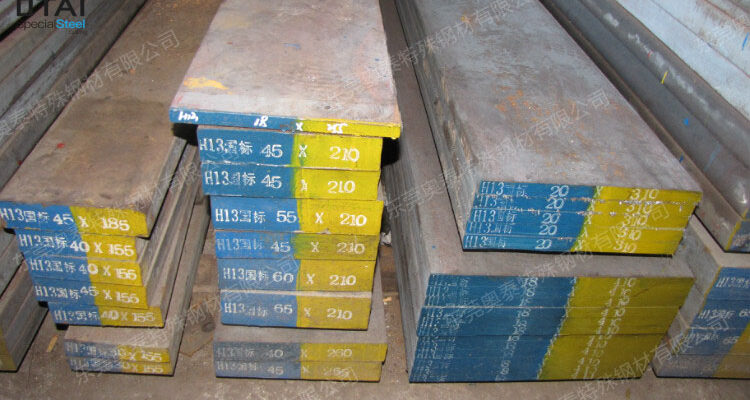

China OTAI Special Steel -H13 TOOL STEEL