H13 STEEL APPLICATION IN LIFE-Chapter 1

H13 STEEL APPLICATION IN LIFE-Chapter 1

1.2344 steel has good mechanical properties and is used widely in industry, such as forming extrusion dies, forging die with large impact load, precision forging die and etc. It can satisfy the needs of the quality requirements of the mold. By the way, the surface of the mold passes through nitriding or cyanidation, the service life of the mold would increase.

H13 Steel Heat Treatment

Annealing

Heat slowly to 1550°-1650°F, hold until entire mass is heated through, and cool slowly in the furnace (40F per hour) to about 1000°F, after which cooling rate may be increased. Suitable precautions must be taken to prevent excessive carburization or decarburization.

Stress Relieving

When desirable to relieve the strains of machining, heat slowly to 1050°-1250°F, allow to equalize, and then cool in still air (Strain Relieving).

Preheat Prior to Hardening

Warm slightly before charging into the preheat furnace, which should be operating at 1400°-1500°F.

Hardening

H13 tool steel is a steel having very high hardenability and should be hardened by cooling in still air. The use of a salt bath or controlled atmosphere furnace is desirable to minimize decarburization, and if not available, pack hardening in spent pitch coke is suggested. The temperature employed is usually 1800°-1850°F, depending on size section.

Quenching

Quench in still air or dry air blast. If complicated forms are to be hardened, an interrupted oil quench can be used. Quench part in oil and remove from the bath when it just loses its color (1000°-1100°F). Finish cooling to below 150°-125°F in air, then tempers immediately.

Tempering

Tempering is carried out in 1.2344 tool steels from 538 to 649°C (1000 to 1200°F) to obtain Rockwell C hardness of 53 to 38. Double tempering can also be performed in these steels for every one hour at the preferred tempering temperature.

H13 Steel Supply

Round Bar

Specification: Dia Max 800mm; Length: 3000-5800mm

Surface: original black, peeled, polished, machined

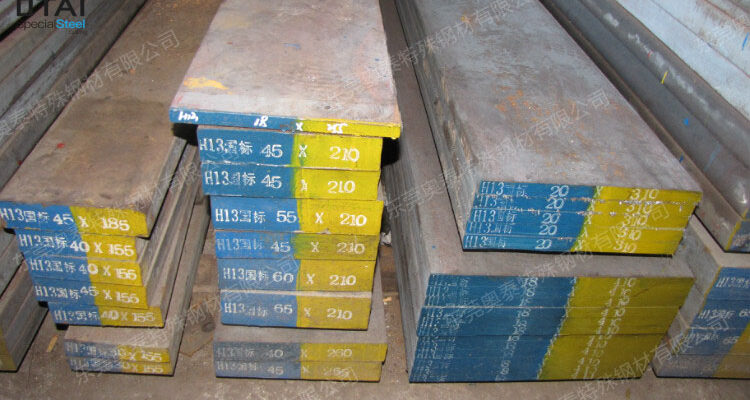

Sheet/Plate/Slab

Specification: thickness: 16-800mm; width: 205-810mm; length: 3000-5800mm

Surface: original black, machined, polished

Notice

We have our own cutting and processing equipment. Specifications can be cut and customized according to your requirements.

We are a professional special steel stockist and supplier with a high-quality stand for many years. As a professional H13 steel supplier, please contacts us for any request. Songshun Steel always with you.

Otai Special steel welcome you soon.