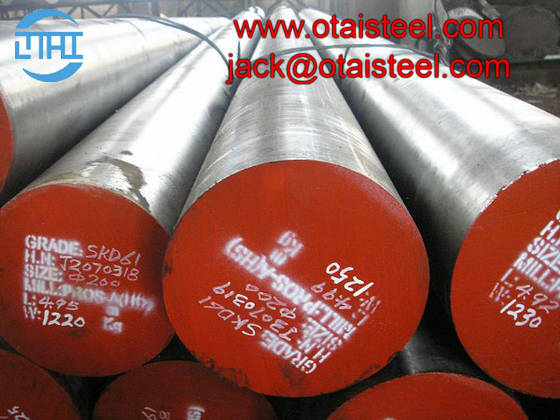

H-21 hot work tool steel, otai will satisfy your demand.

Maybe you heard a lot about hot work tool steel.However, do you know about the h21? H-21 hot work tool steel is perhaps the most widely used of the Tungsten steels. it belongs to the high-quality high carbon alloy tool steel. The 9.5% tungsten content imparts good resistance to softening at service temperatures while still maintaining adequate toughness.

Recently, several clients from Italy ask me whether otai company can provide h21 steel for them, of course, the answer is positive. We sold the h21 steel. They want to import the h21 steel from our company, they build springs, shaped parts and precision metal parts of all types and shapes, in particular for applications in the automotive, motorcycle, household appliances, and industrial plant engineering fields. While h21 is suitable steel for them.

Unlike the higher tungsten grades, H-21 may be cooled by the continuous flow of water if the design of the die will permit. Oil Quenched & Tempered Hardness is 28-34 HRc. AISI H21 steel Annealing delivery hardness less than 250HB.

Chemical Composition

Carbon 0.35

Manganese 0.25

Silicon 0.35

Chromium 3.50

Tungsten 9.50

Vanadium 0.50

Main Application

H21 hot work tool steel is particularly useful for hot forging and blanking dies and punches for making nuts, bolts, and other similar small components. Dies, cores, inserts, pins, etc for the die casting of copper-base alloys are also prime applications for this steel. Other uses include forming dies, shear blades, hot extrusion dies, mandrels, punches, die, holders, ejector discs and extrusion lines.

Due to satisfactory reliable quality and professional service, Otai expands our market worldwide.such as UAE, Canada, Brazil, Colombia, Chile, Spain, Turkey, Algeria, Vietnam, Malaysia and so on. If you are ready to buy tool steel or carbon steel, please choose otai company, you will not regret it.Maybe you heard a lot about hot work tool steel,h13 is widely used tool steel. However, do you know about the h21? H-21 is perhaps the most widely used of the Tungsten hot work steels, it belongs to the high-quality high carbon alloy tool steel. The 9.5% tungsten content imparts good resistance to softening at service temperatures while still maintaining adequate toughness.

Recently, several clients from Italy ask me whether otai company can provide h21 steel for them. of course, the answer is positive. We sold the h21 steel. They want to import the h21 steel from our company, they build springs, shaped parts and precision metal parts of all types and shapes, in particular for applications in the automotive, motorcycle, household appliances, and industrial plant engineering fields. While h21 is suitable steel for them.