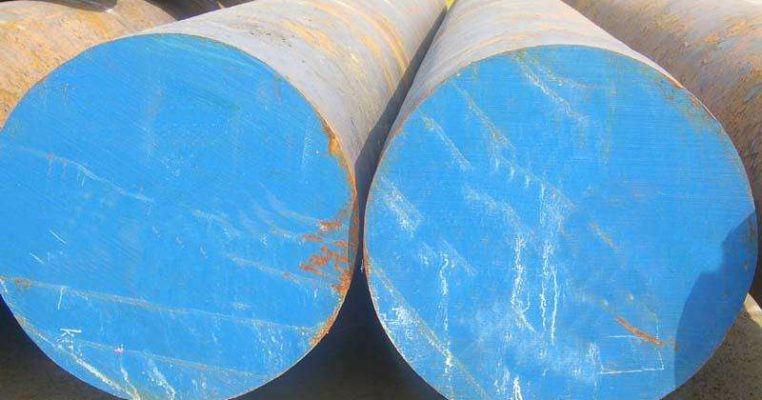

Cr12MoV steel Six-sided forging

Cr12MoV steel Six-sided forging

Cr12MoV steel hexahedral forging,it refers to the combined process of three-way upsetting and drawing.

Each time,A certain forging ratio is required,it make the eutectic carbide gradually,it become irregular and uniformly distributed,or nearly uniformly distributed. Unidirectional drawing is a commonly used method in actual production. The carbides distributed in the network are forged into bands,and the carbides are also broken. This forging process is still feasible for long-axis workpieces, but it is also suitable for molds. In terms of anisotropy,when pulling in one direction,there is obvious anisotropy.Although large die blanks are sometimes forged reasonably,their central structure is still difficult to be significantly improved.

Thallium carbides are stacked in a network and carbides are stacked in a band

Rhenium carbides are randomly and uniformly distributed.The number of upsetting forgings shall be determined according to the specific circumstances, but shall not be less than three forgings and three forgings.

(1) Technical requirements for die forgings

Generally small precision molds with high toughness requirements require carbide unevenness levels of less than or equal to 2, general molds or large molds can be appropriately relaxed.

(2) The level of carbide unevenness in raw materials Cr12Mov.

If the level of carbide unevenness in the supplied steel is high, for example, the electroslag steel ingots that have not been bloom-rolled, the dendritic carbides are very developed and the level of carbide unevenness is high Therefore, it is necessary to repeatedly forge and forge. Even so, it is still difficult to completely change the carbide distribution by forging. For another example, although the large-sized steel used in large molds is rolled, most of the carbides in the center of the steel still remain in a networked distribution. For such large mold blanks, a reasonable six-sided forging must be carried out. Even so, the level of carbide unevenness is often difficult to be lower than 3 levels.

The carbides still have a more or less directional distribution even after a good six-sided forging, so it is necessary to consider that the long side of the mold should be consistent with the rolling direction in order to make full use of its higher longitudinal direction. The outer edge part of the metal with relatively uniform properties and carbide distribution, and the part with the largest hole type and wear, should avoid the center part with the worst quality of the blank as much as possible, because the carbide at this place is the easiest to homogenize.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com