Fixing 4140 steel mold bases: How OTAI Came to the Rescue

Introduction: Down in the heart of Mexico’s steel game, folks are hustling to churn out top-notch steel mold bases for all sorts of uses. But hey, sometimes things don’t go as planned, and that’s where OTAI Steel steps in. We know our way around steel, and we’re all about custom solutions. Let’s dive into a recent gig where one of our Mexican clients hit a rough patch with their steel mold bases production, and how we sorted them out proper.

Unpacking the Problem: Wonky Material Hardness:

First off, our buddy Tomas from Tubos Mexicanos Flexibles dropped us a line about their steel mold bases having some serious issues with inconsistent hardness. That’s a big no-no in the world of Collets, ’cause you want ’em to be tough as nails for whatever job they’re tackling.

Rust Woes:

Then there’s the rust problem. Their 4140 materials were about as resistant to rust as a paper towel in a rainstorm. Not good when you’re dealing with stuff that’s supposed to hold things together for the long haul.

Impurity Blues:

To top it off, there were all these pesky impurities mucking up the mix. These little troublemakers were making it hard to work with the material and messing with the final product’s strength. Not exactly what you want in your steel mold bases.

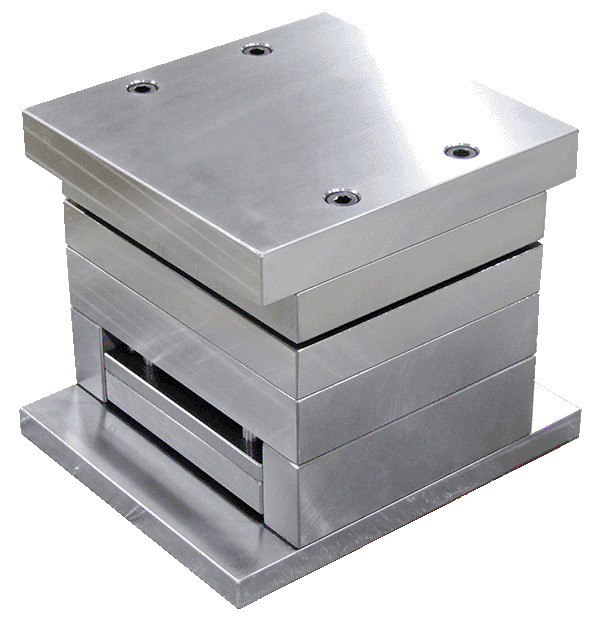

Fixing the Mess: Tailored Solutions from OTAI Steel:

We didn’t waste a second getting down to business. First up, we dialed in a special heat treatment process to even out that hardness issue. Think of it like cooking the perfect steak – precise timing and temperature for maximum flavor. Except we were cooking steel to make it tough and consistent.

Battle-Ready Coatings:

Next, we beefed up our rust-fighting game. Each mold bases got a special treatment before shipping – a bit like giving it a coat of armor. We slapped on some heavy-duty rust-proof coatings and packed ’em up tight to keep those pesky rust demons at bay.

Elemental Detective Work:

Last but not least, we got real Sherlock Holmes on those impurities. We ran some fancy chemical tests to make sure our materials were squeaky clean. No funny business allowed – just pure, top-quality steel going into those mold bases.

Fixing 4140 steel mold bases: How OTAI Came to the Rescue

In a nutshell, we turned our client’s steel mold bases nightmare into a success story. At OTAI Steel, we’re all about rolling up our sleeves and finding solutions that hit the nail on the head. So if you’re in the market for steel that’s as tough as you are, you know who to call. Let’s make some magic happen together.