Which material is common use for metals extrusions

DC53 is common use for metals extrusions

The owner of a metals extrusions factory tell me some experience, the factory is specialized in stainless steel 304 hinge,the thickness is from 2.0 to 3.0mm. He gave me 2 important information. For stamping 304 stainless steel with a thickness of 2.0-2.5, DC53 steel can be used for about 400,000 times. The metals extrusions material will start to burst. In the second case, the stamping thickness is about 3.0 and If the punch of 304 stainless steel is used properly, it will start to burst after punching 70,000 to 80,000 times. From here, you can know that DC53 is common use for metals extrusions,and it’s very practical for metal stamping.But do remember the key is to do a good job in heat treatment.

If you want to know more about it,Please click the link of check as below:

Heat treatment

The steel heat treatment process can be broken down into 4 segments, Hardening (quench) & Tempering.Annealing & Normalized.

Most customers only need make the Hardening (quench) & Tempering for DC53 steel aplication.

- DC53 tool steel heat treatment

JIS DC53 tool steel Forging

Slowly and uniformly Heat the DC53 tool steel to 700°C (1292°F),then rapidly heat the DC53 steel to 900-1040°C(1652-1904°F). After forging slowly cool down.

Hardening | quenching

Heat slowly to 850°C(1562°F), Soak thoroughly at the temperature. the brought up to 1030°C(1886°F)oil quenching or air cool.

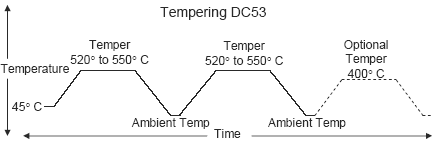

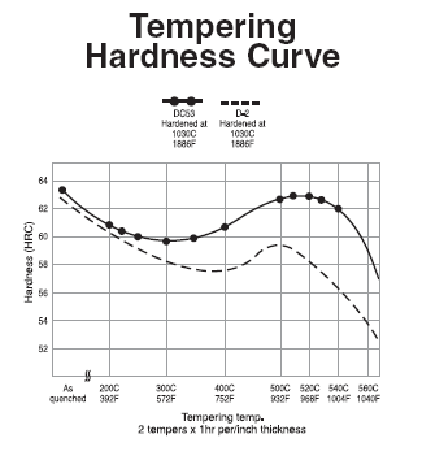

Tool steel DC53 Tempering

Commonly performed Tempering is in a high Vacuum controlled convection furnace. The temper is perfect after Hardening. conducted as soon as the part can be hand at about 45° C (120° F) to 65° C (150° F). by High temperature tempering and hardening, hardness can reached 65 HRC MAX. common application ,we advice the Hardness no higher than 62HRC. Tempering data only for reference as below:

DC53 tool steel Annealing

Normal annealing condition delivery, hardness 255HB MAX. When finished the DC53 Steel tool, then can heat treatment to appropriate hardness.

Regular size and Tolerance

| 1) Hot Rolled round bar | |||

| Diameter (mm) |

Diameter Tolerance (mm) |

Diameter (mm) |

Diameter Tolerance (mm) |

| 6.4~15.8 | -0.038 ~0.038 | 181~<206.2 | 0~1.6 |

| 15.8~<77.6 | 0~0.10 | 206.2~<257 | 0~2.4 |

| 77.6~<103 | 0~0.15 | 257~<307.7 | 0~3.2 |

| 103~<181 | 0~0.78 | ≥307.7 | 0~4.7 |

| 2) Hot Rolled steel plate | |||

| Thickness (mm) |

Thickness Tolerance (mm) |

Thickness (mm) |

Thickness Tolerance (mm) |

| ≤25.4 | -0.41~0.79 | >127~152 | -1.60~2.39 |

| >25.4~76 | -0.79~1.19 | >178~254 | -1.98~3.18 |

| >76~127 | -1.19~1.60 | >254~305 | -2.39~3.96 |

Others have not specified size, pls contact our experienced sales team.

Processing

Round bar and flat sections can be cut to your required sizes. Ground steel bar can also be supplied, providing a high quality tool steel precision ground tool steel bar to your required tolerances. DC53 Tool Steel is also available as Ground Flat Stock / Gauge Plate, in standard and nonstandard sizes.

Contact our experienced sales team to help you with your DC53 questions

by email-sharon@otaisteel.com or telphone. The questions will be reply in 24 hours.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com