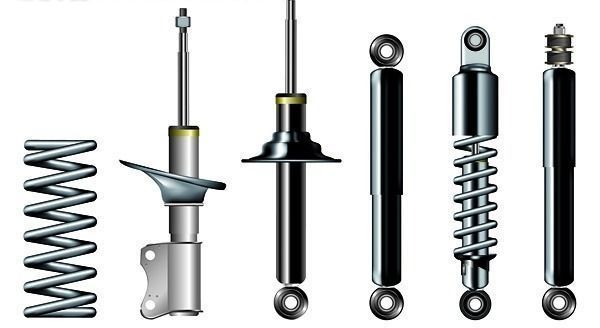

Springs are the most commonly used parts in the machine industry and everyday life. For many people, springs should have been used. It is common that the ballpoint pens we use are equipped with springs. The springs that can be seen everywhere in our daily life belong to spring steel. Small ones can be used as parts. Large ones can be used as exercise equipment for exercising. Springs are a kind of parts that use elasticity to work. They are generally made of spring steel. Made of raw materials. This kind of spare parts is not only often visible in our daily life, but also used in many mechanical equipment. Because springs are widely used, there are many market demands.

We often use springs in our lives, such as springs in automatic ballpoint pens, springs in tensioners, springs in sofas, etc. Therefore, spring steel exists in all aspects of our lives. From small mobile phones, clocks, computers, large ships, and airplanes, the components are inseparable from springs. Springs are important for machinery and equipment.

In addition, when you are in the gym, the gym equipment is more comprehensive. Many fitness equipment we often use, such as treadmills, dumbbells, exercise bikes, etc., all of which require steel. This professional equipment generally needs to be used. Steel. High-quality steel equipment is more conducive to our effective fitness and fat reduction, you can choose the fitness equipment that suits you according to your fitness goals.

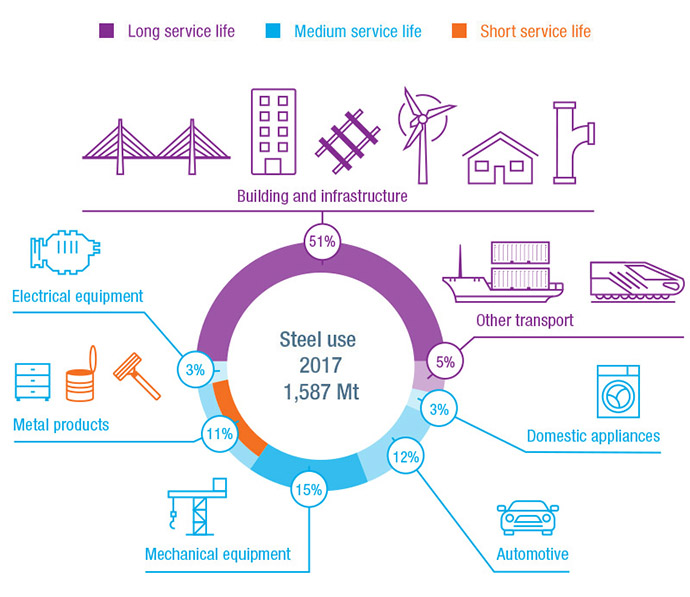

In our daily lives, steel products have become a safety guarantee. Everyday transportation, common cars, buses, subways, high-speed trains, and airplanes all pay attention to the strength of steel. It is because of this high-strength steel that we can travel with peace of mind. 1045 steel and

In our daily lives, steel products have become a safety guarantee. Everyday transportation, common cars, buses, subways, high-speed trains, and airplanes all pay attention to the strength of steel. It is because of this high-strength steel that we can travel with peace of mind. 1045 steel and  Demand for steel in developing countries continues to recover, but there are challenges

Demand for steel in developing countries continues to recover, but there are challenges

Although steel is considered to be one of the most cyclical materials, especially due to its infinitely recyclable nature, the wider implementation of circular economy principles (such as reduction, reuse and remanufacturing) will have a profound impact on China.

Although steel is considered to be one of the most cyclical materials, especially due to its infinitely recyclable nature, the wider implementation of circular economy principles (such as reduction, reuse and remanufacturing) will have a profound impact on China.