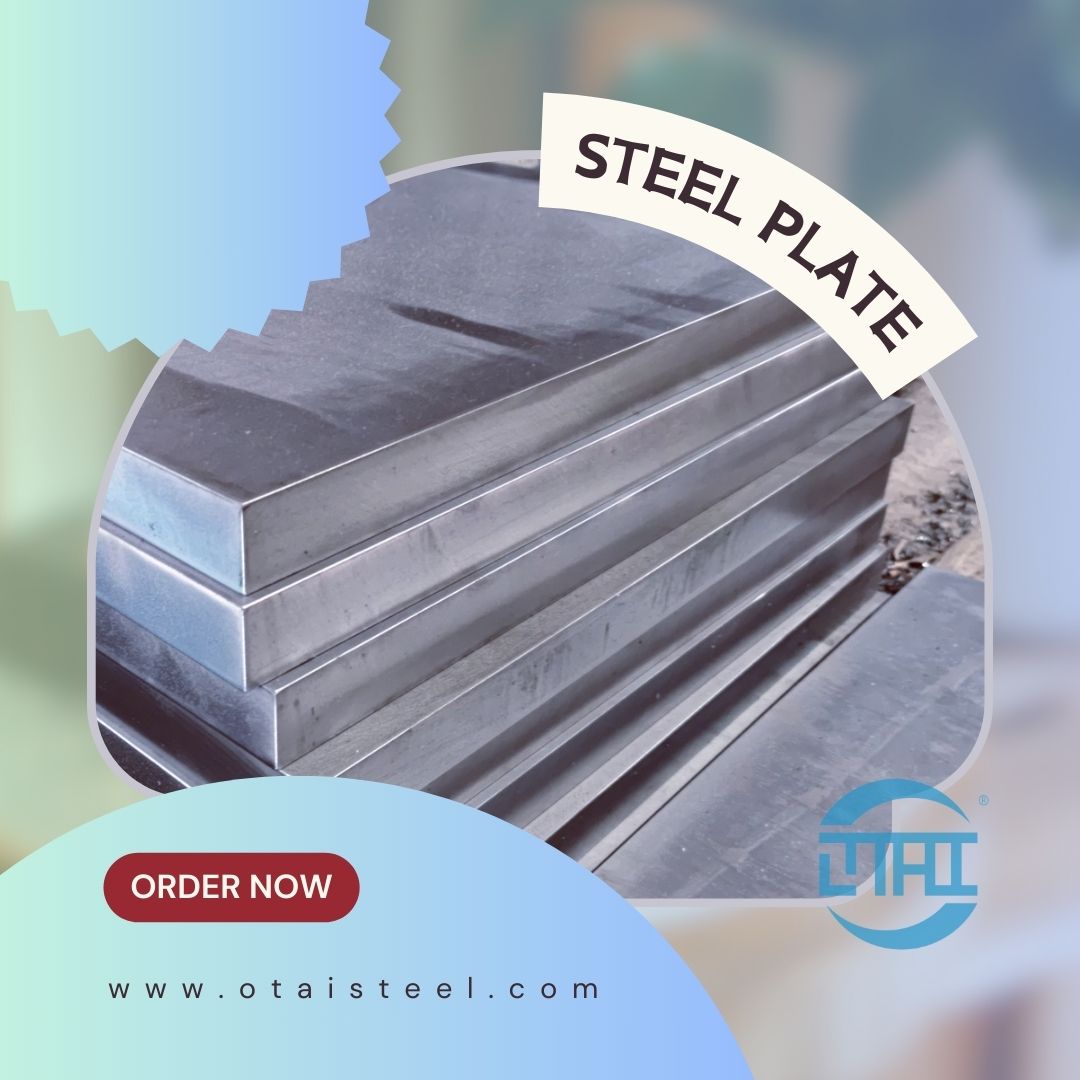

material 34crnimo6 equivalent: Your Reliable Choice at OTAI

Welcome to the world of steel where strength, reliability, and flexibility matter the most. As a seasoned steel stockist, we understand the demands of the industry. Our 34CrNiMo6 steel is designed to meet and exceed your expectations. In this article, we’ll explore the exceptional qualities of 34CrNiMo6 steel. Peppered with practical insights and real customer success stories. Making a compelling case for why OTAI is your go-to partner in the steel business.

34CrNiMo6 Steel: The Backbone of Durability

34CrNiMo6 steel is more than just a material. It’s a solution that empowers your projects with its unique blend of toughness, high tensile strength, and versatility. Whether you’re in automotive, aerospace, or manufacturing, this alloy is designed to withstand the toughest conditions and deliver consistent performance.

Why Choose OTAI for Your 34CrNiMo6 Steel Needs?

- Always in Stock, Always Ready: At OTAI, we understand the urgency of your projects. That’s why we pride ourselves on having 34CrNiMo6 steel in stock all year round. No more waiting or delays – all sizes are readily available. Ensuring you have the materials you need when you need them. And if you have specific requirements, our quick customization services have got you covered.

- Packaging Solutions Tailored to You: We believe in providing a hassle-free experience from start to finish. Our packaging services include cable tie packaging and wooden box packaging. Ensuring your materials are secure and ready for use upon arrival. Worried about rust? Relax, our rust-proof packaging is designed to keep your steel in pristine condition.

- Trusted by Global Giants: We take pride in being a preferred supplier to some of the world’s top 500 companies. Our track record speaks for itself. When you choose OTAI, you’re choosing a partner that understands the demands of the industry. Our deliveries are not just timely; they are in full compliance with the given technical requirements. Our customers are not just satisfied; they are thrilled with the quality and precision of our 34CrNiMo6 steel.

Real Customer Success Stories:

Case 1:

A Construction Marvel A leading construction company turned to OTAI for a massive project requiring a substantial amount of 34CrNiMo6 steel. Tight timelines and complex specifications were no match for our dedicated team. The result? A successful project completion that exceeded the client’s expectations. The quick customization and timely delivery turned this client into a long-term partner. Relying on OTAI for all their steel needs.

Case 2:

Driving Innovation in Automotive An innovative automotive manufacturer sought a reliable supplier for a crucial component in their latest model. OTAI’s 34CrNiMo6 steel not only met the strict technical requirements but surpassed them. The materials were delivered promptly, contributing to the successful launch of a groundbreaking vehicle. Today, this automotive giant continues to choose OTAI as their trusted steel supplier.

In the competitive landscape of steel wholesalers and distributors. OTAI emerges as a reliable partner that understands the language of the industry. Our material 34crnimo6 equivalent, always in stock, customizable, and backed by top-notch packaging, is your ticket to success. Join the ranks of satisfied customers who have experienced the OTAI difference. When you choose OTAI, you’re not just buying steel. You’re investing in strength, reliability, and a partnership that stands the test of time.