4140 steel crankshafts -Why choose 4140 Steel for making crankshafts?

Introduction: Looking for a steel that’s tough as nails and reliable as your best buddy? Enter 4140 steel – the unsung hero of a ton of industries. From building big machines to making precise tools, this alloy steel is like your Swiss Army knife. Let’s dive into why 4140 steel from OTAI is the bomb.

4140 steel is the MVP for any job that needs muscle. Whether you’re building heavy-duty crankshafts or fine-tuning gadgets, this alloy this alloy is excellent. It’s like the Jack-of-all-trades, ready to roll in any situation.

Choose OTAI for your 4140 Steel supplier:

The Real Deal At OTAI, we’re all about hooking you up with the best of the best. Here’s why our peeps keep coming back for more:

- Stocked Up: Need 4140 steel, like, yesterday? We’ve got your back. We’ve got a boatload of it in stock, all year round. And we’re talking all sizes, ready to be pimped out to fit your needs pronto.

- Packaging Perfection: No more headaches over how to get your steel from point A to point B. We’ve got packaging options galore – from keeping it snug with cable ties to rust-proof wooden boxes. Your order will arrive safe and sound, no sweat.

- Trusted by the Big Guns: Rubbing elbows with the big shots? We’ve hooked up the world’s top dogs with our 4140 steel, and they’ve been singing our praises ever since.

Why choose 4140 alloy steel for making crankshafts?

4140 forged steel boasts impressive mechanical properties. It offers high tensile strength, good ductility, and excellent impact resistance. These properties make it suitable for making crankshafts.

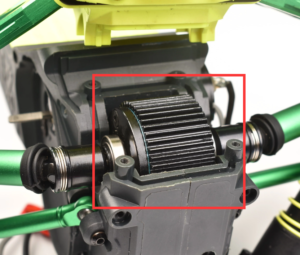

Application of 4140 steel in crankshafts:

Forged Chromoly crankshafts are machined from a 4140 Chromoly forging. Cromoly is one of the strongest metals that can be used to make crankshafts.

Progressive dies are used in the forging process to ensure grain flow that conforms to the shape of the finished crankshaft.

The special counterweight design helps reduce (oil) foaming in high-revving engines while smoothing out the entire power range of your engines. Built-in counterweights flatten harmonics at high speeds and dampen engine vibrations.

Forged chromoly crankshafts are the natural choice for high-performance engines or greater reliability in your street engine.

Interesting story

Paul wants 4140 steel for producing crankshafts. We provided him with different sizes of steel round bars and fast delivery. He is happy that we have completed a very comfortable purchase.

Ready to Rock with 4140 alloys? Ready to kick your projects into high crankshafts? OTAI’s got your back with our top-notch 4140 steel. It’s tough, it’s versatile, and it’s backed by a crew that knows their stuff. Get in touch today and let’s take your projects to the next level with 4140 material by your side.