Introduction to AISI 4140 Alloy Steel

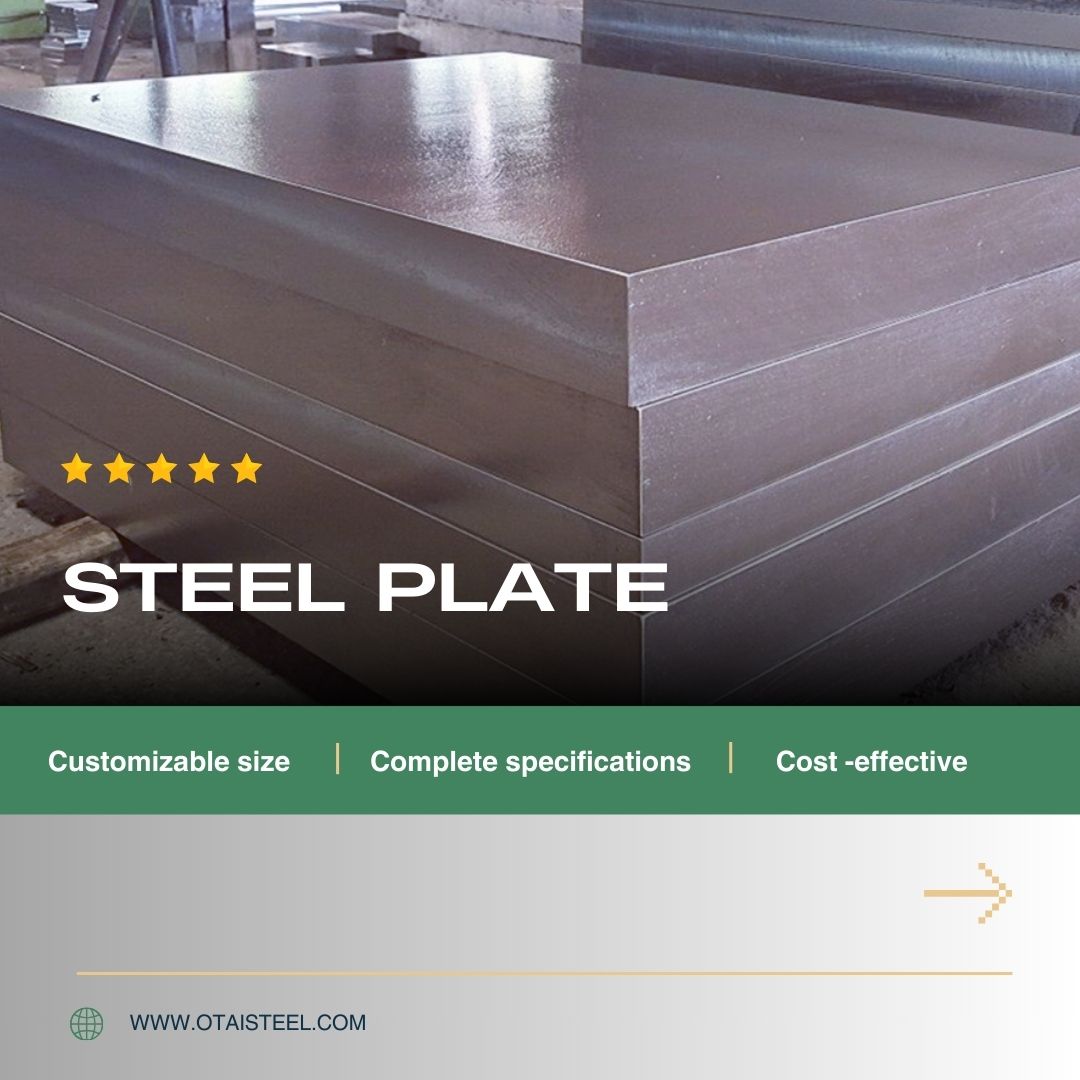

Looking for strong, reliable steel plates? Meet AISI 4140 alloy steel. It’s tough, versatile, and perfect for tough jobs in automotive, oil and gas, and machinery industries. At OTAI Special Steel, we specialize in providing top-notch AISI 4140 alloy steel plates tailored to your needs.

Why Choose AISI 4140 Alloy Steel?

AISI 4140 is known for its strength and durability. Whether you need hardened, tempered, or annealed plates, it’s your go-to for gears, shafts, bolts, and more. At OTAI, we make sure our steel plates deliver top performance and last long in your projects.

OTAI’s Commitment to Quality and Reliability

At OTAI Special Steel, we take pride in what we do. Here’s why customers choose us:

1. We’ve Got What You Need

We keep a big stock of AISI 4140 alloy steel plates in different sizes. Need them fast? No problem. We’re quick on delivery and can customize sizes to fit your project perfectly.

2. Safe Delivery, Guaranteed

Worried about shipping? Don’t be. We package your steel safely with straps or wooden crates to protect it from rust and damage. Your steel arrives safe and sound, ready to work.

3. Trusted Worldwide

Top companies worldwide trust us with their steel needs. We meet strict standards and delivery times, keeping our customers happy and their projects on track.

Customer Stories

Case Study: Precision Machinery Co., Ltd.

“OTAI’s steel is top-notch. Their quick service and quality keep our production running smoothly. Perfect for our high-performance components.”

Case Study: Global Automotive Parts Inc.

“OTAI’s custom sizes and strong packaging have made our supply chain a breeze. They’re spot-on with quality, which we need for our parts.”

AISI 4140 Alloy Steel Plate Price: Get the Best Deal

Looking for AISI 4140 alloy steel plates? Look no further than OTAI Special Steel. We’re all about quality, custom solutions, and keeping customers happy. Contact us now to get the best deal on AISI 4140 alloy steel plates. Trust OTAI for steel that works as hard as you do.

For more info and orders, visit OTAI Special Steel. Get your AISI 4140 steel plates today!

Understanding the Uses of 4140 Tool Steel Plate

Understanding the Uses of 4140 Tool Steel Plate Reliable 4140 Steel Supplier for Plate Projects

Reliable 4140 Steel Supplier for Plate Projects Choosing the Better 4140 Steel Supplier for Cut Plate

Choosing the Better 4140 Steel Supplier for Cut Plate Why Choose 4140 Steel Plate in the UK?

Why Choose 4140 Steel Plate in the UK? Choosing the Right Thickness for Your 4140 Steel Plate

Choosing the Right Thickness for Your 4140 Steel Plate Finding Reliable 4140 Steel Plate Suppliers in the UK

Finding Reliable 4140 Steel Plate Suppliers in the UK

4140 Steel Plate Specification: What You Need to Know

4140 Steel Plate Specification: What You Need to Know