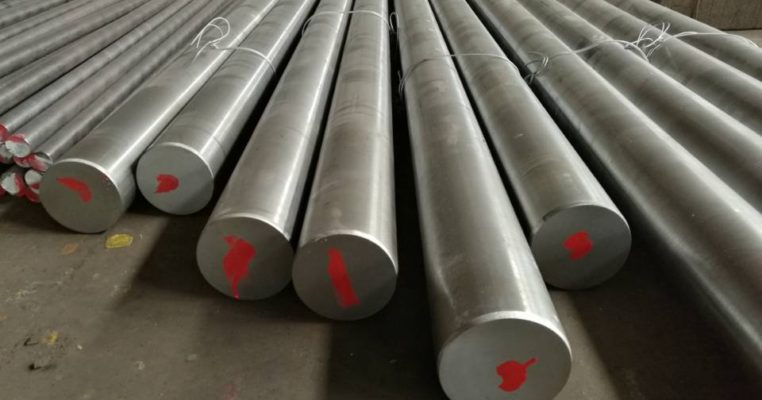

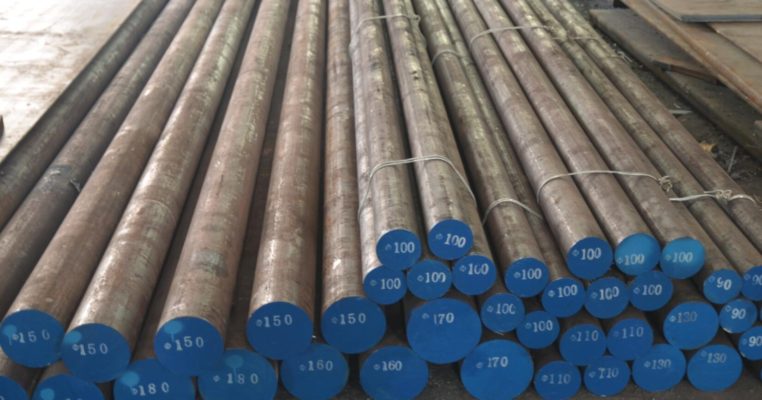

OTAI Special Steel keep high level stock for 34CrNiMo6 round bar. We can support our customer regular size Φ10mm to Φ500mm. We support quickly shipping time, 2 hours after-sale response, 2 days earlier than expected, hard for competitors to do this. OTAI Steel have professional quality control system. There is 8 consecutive years no quality event complain, over 80% repeat order rate.

34CrNiMo6 round bar overview

34CrNiMo6 is DIN standard alloy steel, can be used as equivalent for AISI 4340. We supply a lot of this material regularly to South America market. Our customers include steel distributors, and end users like vessel parts and oil equipment parts manufacturers as well.

Peru customer story

We have a Peru customer Mr M, who is market player for special steel in local market, buy OTAI Steel 1045 and 4140 since 5 years before. Mr M concern China quality, so insist buy 34CrNiMo6 round bar from North America for many years, much more expensive of course.

Since 2018, OTAI focus on improving sales revenue for CrNiMo steel, we keep daily stock 500 to 800 tons for 34CrNiMo6 round bar, include small diameter 34CrNiMo6 round bar Φ10mm, also big diameter 34CrNiMo6 round bar Φ500mm, price is also more attractive than before. Mr M show his interesting about what we do, but still do not decide to buy, because his quality concern, again.

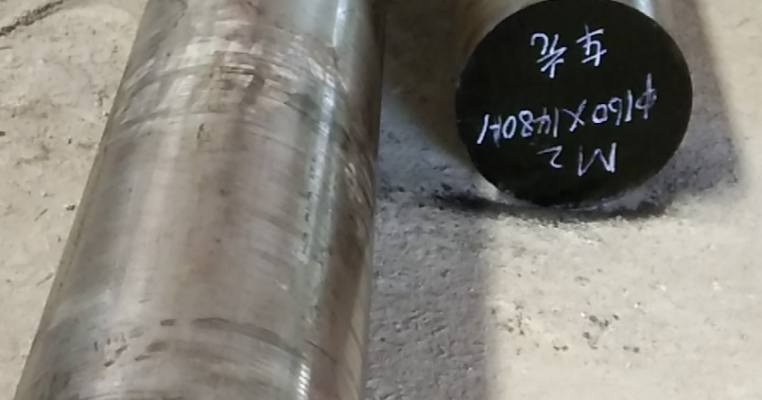

This April, OTAI Steel signed contract with Saudi Arabia tender project which use OTAI material 34CrNiMo6 round bar. This project is proceed by one of our Asia customer, ender user is a Saudi Arabia tender project. The project will last 3 years. Our customer win the bid for material 34CrNiMo6 round bar and 1045 round bar. We supply 34CrNiMo6 round bar to them. The first stage they order 9 containers to us, split to 3 batch, 3 containers each batch, each batch they require SGS inspection on site, and inspection standard is EN BS 10343-2009. SGS inspection items as below:

1) Chemical composition: Test method ASTM E415-2017

2) Tensile test: include tensile strength, yeild strength, elongation, reduction of area. Test method EN ISO 6892-1-2016

3) Impact testing: Test method EN ISO 148-1-2016

Result: OTAI 34CrNiMo6 round bar comply with customer required standard EN BS 10343-2009

We have great sincerity to work with Mr M about 34CrNiMo6 round bar, so we keep this Peru customer aware each step and detail of SGS inspection. This October, we completed all three batch 34CrNiMo6 round bar, and shared with Mr M total three different SGS inspection report. This November Mr M sign contract with OTAI Steel. We are really happy to get trust from this customer, who have high quality requirement.

OTAI Promise, we undertakes every order to end and solve customer’s problem without any hesitate on responsibility.

Ms Susie Li

Mobile/WhatsApp: 0086-13826999755

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Susie@otaisteel.com