Classification of high-speed steel:

- Basic high-speed steel: omitted

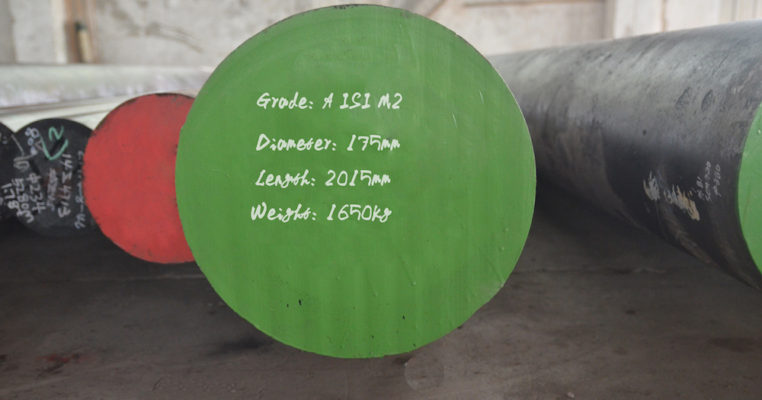

- General-purpose high-speed steel: Representative steel: M2

Did you choose the right high speed steel M2 for the cutter?

Tool classification:

The first category: 1. Carbon tool steel cutting tools

2.Alloy tool steel cutter

The hardness is between HRC60-63,suitable for low-speed cutting, and the red hardness is 350. the following.

The second category: high-speed tool steel cutting tools

1. General-purpose high-speed steel cutters with hardness between HRC60-63;

2. Super-hard high-speed steel cutters with hardness between HRC66-70.

Suitable for high-speed cutting, with red hardness of 600. the following.

The third category: 1. Carbide cutting tools: (powder) WCCo alloy

1, cubic boron oxide;

2. Diamond cutter: (cannot process steel)

3, ceramic tools: red and hard in 800-1200. between.

Classification of high-speed steel:

1. Basic high-speed steel: omitted

2. General-purpose high-speed steel:

The most representative steel abroad: High speed steel M2—W6Mo5Cr4V2

The most representative steel in China: W9—W9Mo3Cr4V; W18—W18Cr4V

3. Super-hard high-speed steel: Representative steel—M42

The most representative steel abroad: Co-hardened ① United States: M42—W2Mo9Cr4VCo8;② Germany: W10Mo3Cr4 V3Co10

If you need more information of high speed steel M2 or other high speed steel for cutter,please do not hesitate to contact me.

M2 high speed steel Related Specifications ASTM A600-1999 M2 HSS steel data pdf down

Related Specifications and Equivalent of ASTM M2 high speed tool steel with others HHS Material Standard

| Country | American | Germany | Japanese | Chinese |

| Standard | ASTM A600-1999 | DIN 17350-1980 | JIS G4403-2000 | GB/T 9943-2008 |

| Grades | M2 | 1.3343 | SKH51 | W6Mo5Cr4V2 |

| Grade NO. | C(%) | Si(%) | Mn(%) | P(%) | S(%) | Cr(%) | Mo(%) | V(%) | W(%) |

| M2 | 0.78~0.88 | 0.20~0.45 | 0.15~0.40 | ≤0.030 | ≤0.030 | 3.75~4.50 | 4.50~5.50 | 1.75~2.20 | 5.50~6.75 |

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com