O1 cold work tool steel -What are the O1 cold work tool steel’s mechanical properties

With over 20 years’ pre-sales and after-sales special steel, Otai helps distributors and end-users to avoid all possible swindle and cheat. Our steel materials meet DIN / ASTM / EN / JIS etc different international standards. O1 cold work tool steel is a high-quality Cold work tool steel, It belongs to the high-quality high carbon alloy tool steel.

O1 tool steel is a high-quality cold work tool steel, It belongs to the high-quality high carbon alloy tool steel.

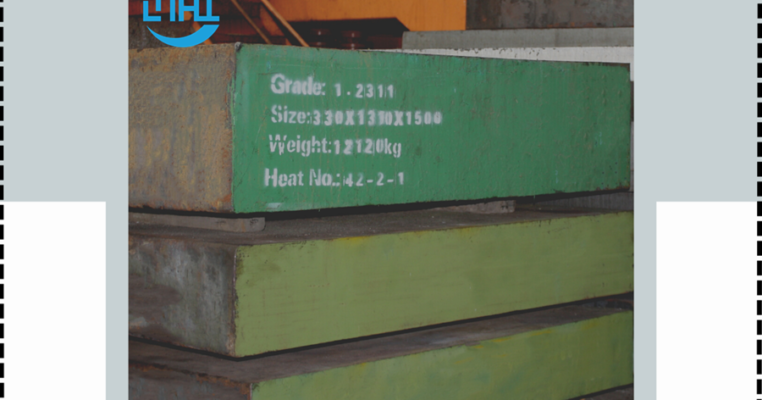

Oil quenched & tempered hardenss is 28-34 HRC. O1 steel Annealing delivery hardenss less than 250HB.

O1 steels are mainly used for short-run tooling for cold forming dies, blanking dies, and cutting tools operating at ambient temper.

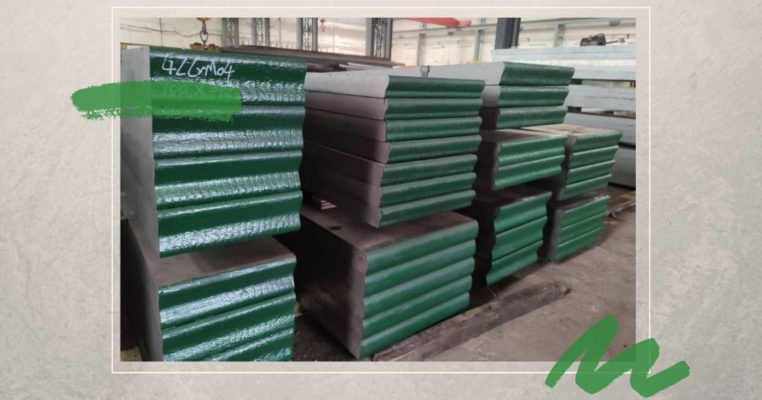

O1 tool steel typical applications include medium run dies and intricate press tools. Also include drawing punches, broaches, bushings, and lathe centers. Including chuck jaws, master cavity sinking hobs, and paper cutting machine knives. Including plug gauges, thread gauges, and precision measuring tools. Also commonly used in applications such as cams, cloth cutting knives, and cold taps. Including reamers, collets, cutting hobs, strip slitting cutters, trimmer dies. Including tube expander rolls, plastic molds, and woodworking knives.

Customer’s story

We would like to share a real case of our customer with you. Dave from Pakistan sent us an inquiry for O1 steel plates. As time is tight, he needs to receive the goods within 45 days. That’s no problem for us because we keep a daily inventory of 1000 tons. After the customer placed his order, we have prepared his O1 steel plates to ready the next day. We also assisted the customer to find the fastest delivery, and the goods were delivered to the customer in 45 days.

8 consecutive years no quality event complain, over 80% repeat order rate. Otai undertakes every order to end and solve customer’s problems without any hesitation on responsibility. When customized special steel is hard to get, Otai settles satisfactorily completely.