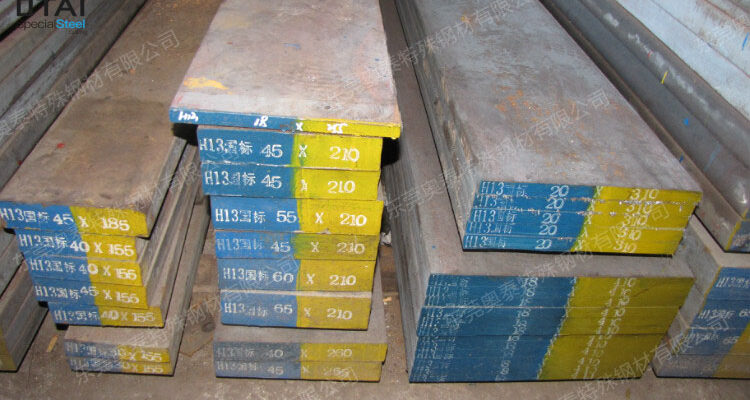

H13 application –Chapter 8

H13 steel is the most widely used of the hot work mold steel in the world. H13 has great heat intensity properties, hardness and wear resistance. The toughness and anti-fatigue performance of H13 are good.H13 is widely used to make all kinds of hammer dies, hot-extrusion dies and etc. H13 -Hot die steel needs to sustain huge impulse load, friction and high-temperature oxidation. But h13 something always happens during work time. Such as the crack, dent, abrasion, formation of cracking and etc. The chemical composition chart of H13 die steel as below.

Its characteristics of chemical composition of H13

H13 carbon content can make sure the high hardness, toughness and other properties.

Adding the elements Cr, Mn, Si, Mn, H13 can make the hardenability get better to change the nature and shape of the oxide in the time of steel become solidification. H13 That move can avoid the formation of low melting point Fes on the grain boundary. Instead, existence as Mns with certain plasticity. Then it will clean out the bad influence of sulfur to make the hot workability of H13 mold steel. Adding the elements of Mo, V to make it harden secondary. And it can enhance temper resistance.

The factors of failure-H13 STEEL

H13 is a complicated question. But we can analysis it on four ways of material, design, manufacture and use.

- Chemical composition and the quality of material of H13

H13 steel belongs to the type of graphitic alloy steel. H13 have so many nonmetallic inclusion in it. And H13 has the defects of the center be loosen and etc. H13 will make the strength, toughness and etc get down. And the quality of H13 steel has two levels for common and high-quality. High quality H13 steel is made from high technology and material. H13 has better toughness and thermal fatigue property. However, the common one needs the processing of forging. H13 will destroy the big non-metallic inclusion and make the carbide get small.