Not many people use 42CrMo4 Plate annealed,as my experience,most of them would like to take the natural one or Q+T condition,but

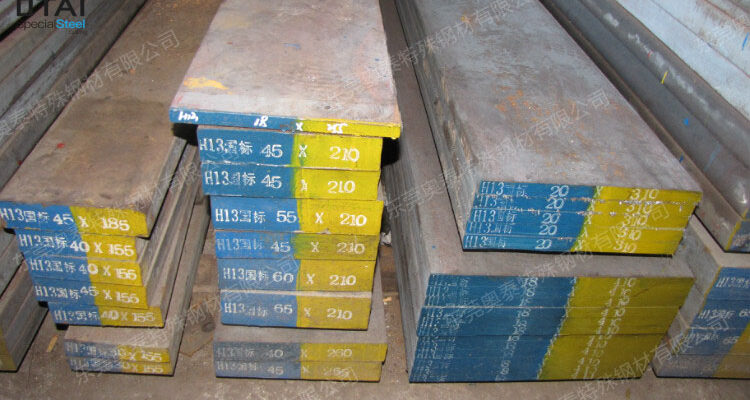

Not many people use 42CrMo4 Plate annealed,as my experience,most of them would like to take the natural one or Q+T condition,but some special factory they would like to take the 42CrMo4 Plate annealed directly,as they demand the hardness:16-22 Hrc,it would be easier to machine easier.

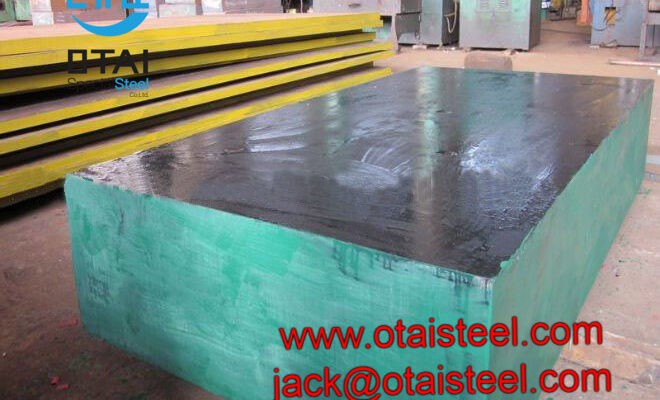

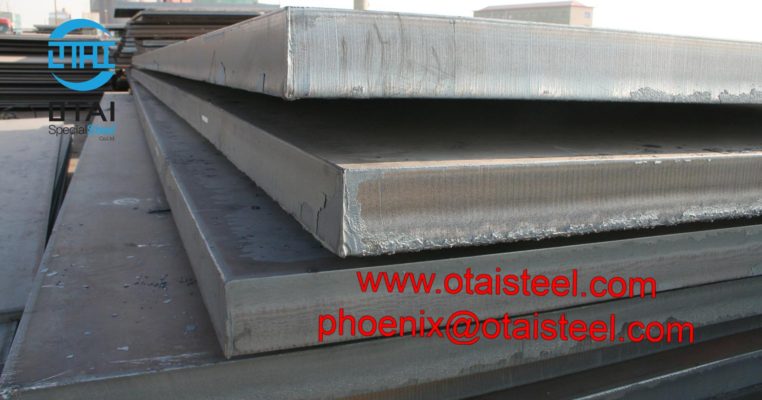

In fact,we don’t have much 42CrMo4 Plate annealed in stock,we also keep the 42CrMo4 Plate in Q+T or natural condition most,but we have our own heat treatment factory partner,and we had cooperated for over 7 years,so we could make it as annealed condition by 1 week,I guess most of people could accept it.

We exported the 42CrMo4 Plate material to the Uddeholm which is the 500 groups company.

At last, we sold a lot of this steel grade to the South of America. Moreover, many trading companies in China also purchased this steel from us for exporting to their overseas customers.

Each year, the sales quantity for this steel material is the Top 1 in our company.

We could provide the one stop solution service. Therefore most of the customers place the 42CrMo4 Plate annealed order to us without any worry. If they need the fixed length and size, or need to cut it in flat bar, we could cut it in our factory by oursides. That is because we have our own cutting machines. Besides, we also have our own testing instruments for making sure the quality.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com