In 2020 , we prepare 42CrMo4 Round Bar Hot Rolled Export to abroad almost with 3000Tons . With any shape in sheet plate and round bar and flat bar and square bar and other request by customer . After long time holiday Chinese Spring Festival , this is our first week to come back to work in the office . Thanks for all the regular customer’s concern . We are safe and healthy very well . All the people here are fine , Wuhan is OK now , and China also very well now .

As all the client know that China have outbreak New coronavirus pneumonia , this is truth . But the main epidemic situation is only in Wuhan , which is under control . The government is actively taking many measures to deal with it . Other cities have little impact . And now are have come back to working with facemasks , please believe that it have to be restored already .

From here , we will work like before . We have more 16 years experience in 42CrMo4 Round Bar Hot Rolled , steel plate, flat bar, square supply. 42CrMo4 alloy steel is chromium, molybdenum, manganese containing low alloy steel. It has high fatigue strength, abrasion and impact resistance, toughness, and torsional strength. The following datasheet gives an overview of 42CrMo4 alloy steel.

42CrMo4 alloy steel material is a high quality Quenched and Tempered Alloy Structural steel, It belong to the high quality medium carbon alloy steel, Oil Quenched & Tempered Hardenss is 28-34 HRC. 42CrMo4 Annealing delivery hardenss less than 250HB.

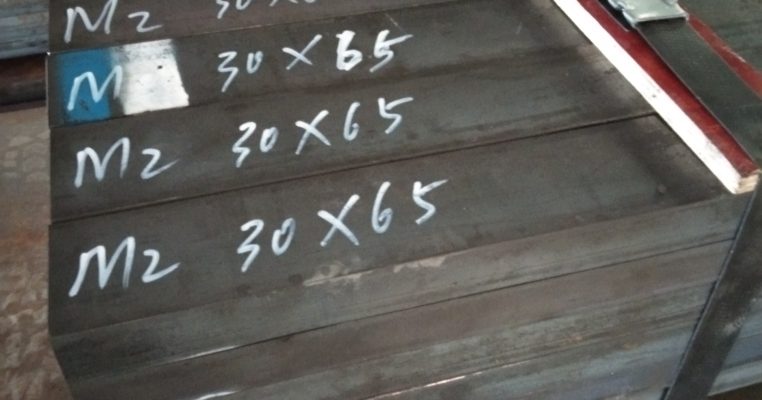

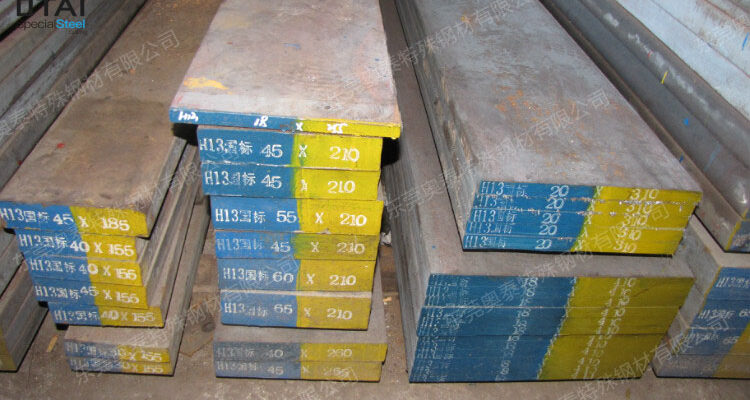

42CrMo4 Round Bar Hot Rolled Export and flat sections can be cut to your required sizes. 42CrMo4 tool steel ground bar can also be supplied, providing a high quality tool steel precision ground tool steel bar to your required tolerances. SAE 4140 steel is also available as Ground Flat Stock / Gauge Plate, in standard and nonstandard sizes.

With all the conditions , we believe that 42CrMo4 Round Bar Hot Rolled Export to other country in 3000Tons was a piece of cake .

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: jack@otaisteel.com