The coronavirus is the hottest issue all over the world .compared with the February, the epidemic is under-control now in china. our government takes a lot of measures to resume the development of economic.

Will the steel industry be affected by the epidemic? I don’t think so.

As reported, 90 key railway projects in China resume construction. with 199,000 people starting working at the construction sites in question, as announced by China Railway Corporation (CRC).

Meanwhile, CRC is actively promoting preliminary work at other major railway projects. including the Sichuan-Tibet railway, the Chengdu-Chongqing high-speed railway. the Xi’an-Chengdu high-speed railway is also included. CRC is pushing to start construction on such projects as early as possible.

Meanwhile, CRC has run 115 special trains to transport workers.It transporting 123,000 people to go back to work. Railway passenger traffic in China has risen each day since February 20.thus providing solid support for the resumption of production in China. because the shortage of labor is the biggest problem facing the industry in China at the moment.

Previously, China’s Ministry of Finance announced that it will carry out a proactive fiscal policy to support the construction of key projects.It will boost demand for steel. So the steel industry will not be affected by the epidemic .the demand for steel will be increasing soon.

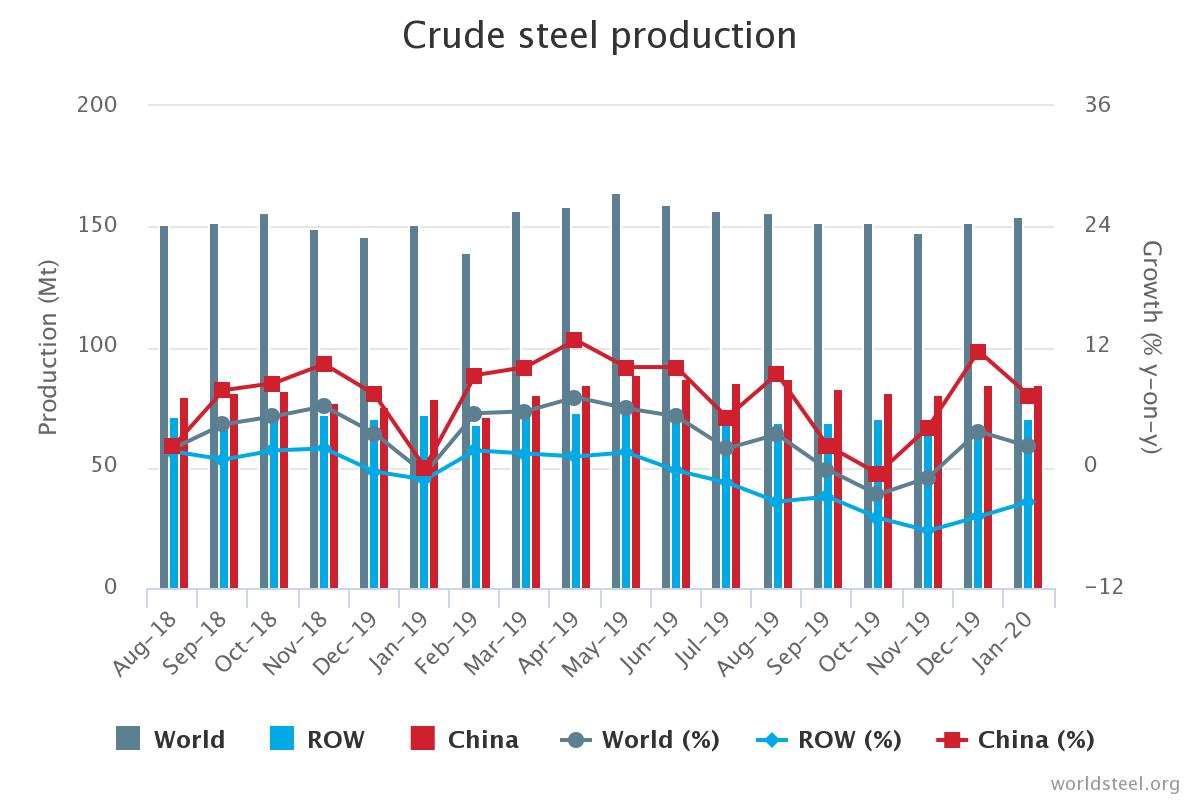

After analyzing the statistics of the crude steel production I mentioned before, we can find that steel production in China still keeps increasing.

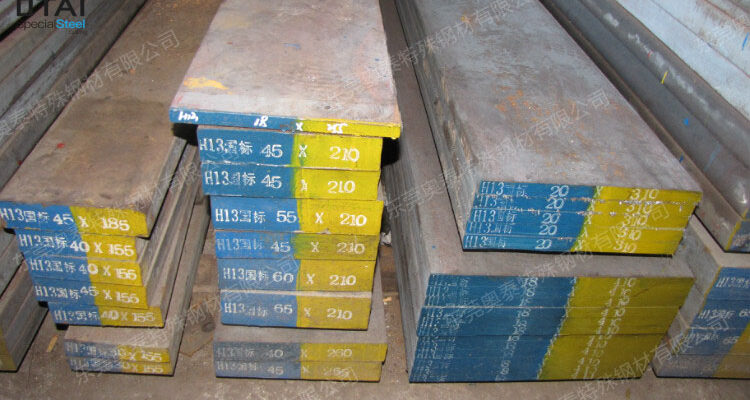

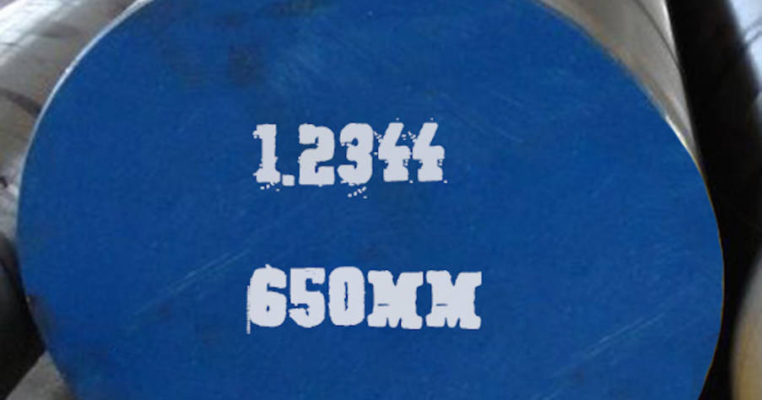

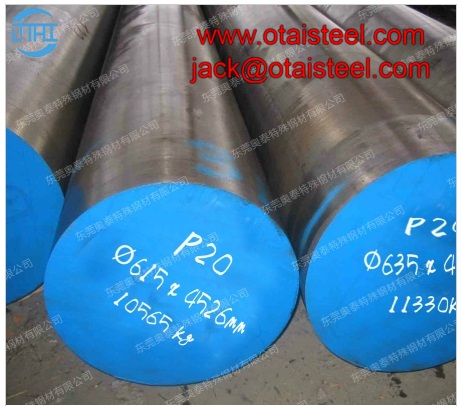

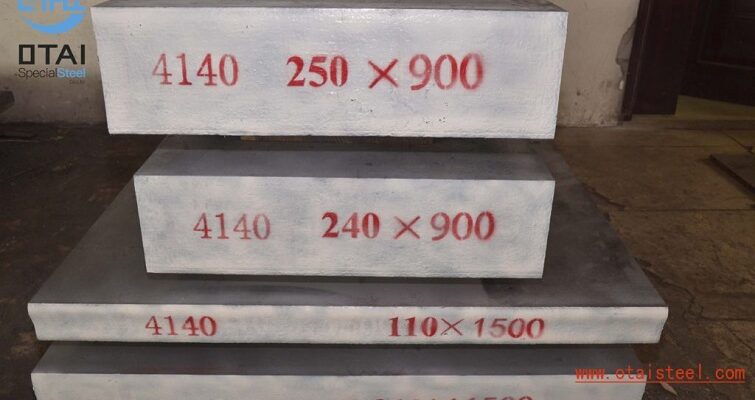

Otai Steel supplies a wide range of carbon, alloy, and stainless steel products. including high-speed tool steel, cold works tool steel, hot works tools steel, plastic mold steel, engineering steel and machine structural steel, etc.

After almost 20 years of development and growth, Otai Steel becomes one comprehensive special steel factory, stockist and exporter. If you want to know more about us, please feel free to connect with me.