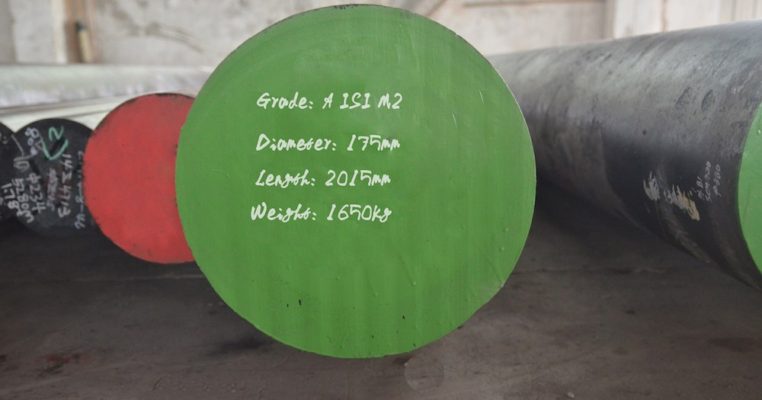

42CrMo4 Steel Pipe Stocklist For Sales Promotion from China after coronavirus . In March , we have received many demands for 42CrMo4 Steel Pipe . Luckly we have many stocklist for this production . And all the measure are according to Chinese regular production size . One out diameter have many different wall thickness to choose .

42CrMo4 Steel Pipe Stocklist For Sales Promotion from China after coronavirus from OTAI Special Steel . In March , We have received new inquiry from Turkey , Argentina …… for 42CrMo4 Steel Pipe . And recently we have planned to provide sales promotion for this materials . Because for we have many stock in various out diameter and wall thickness to meeting all your request . Please contact with us urgently . The Inventory is reduced daily . The stock may sold out for some special size .

42CrMo4 Steel Pipe Stocklist Mechanical Tubing are medium carbon alloy grades . Which are widely used for many general-purpose applications that require high tensile strength and toughness . Alloy tubing is an excellent candidate for most processing techniques . Where strength is required and allows for many options due to its available sizes produced .

42CrMo4 Steel Pipe Stocklist alloy tubing is easiest of the common alloy grades to be machined . With a minimal stock allowance for clean-up . It has excellent machining characteristics and is a medium carbon alloy.

42CrMo4 Steel Pipe Stocklist is usually supplied ready heat treated to hardness in 18-22 HRC . If further heat treatment is required, then heat to 840 oC – 875 oC, hold until temperature is uniform throughout the section . Soak for 10 – 15 minutes per 25 mm section, and quench in oil, water, or polymer as required .

Welcome to inquiry with us 42CrMo4 steel pipe , and we also have other steel pipe AISI 1020 and 1045 . Some less quantities with 4130 tubes , please send request for get the quotation .

jack@otaisteel.com

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: jack@otaisteel.com