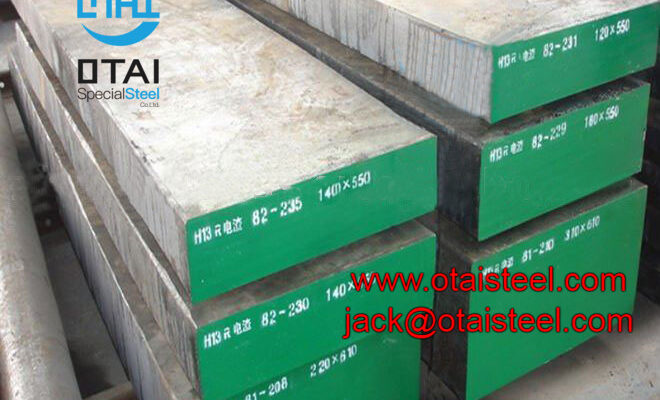

1.2344 Saw Cut Sheet Plate for Auto Parts Mould Use provided by OTAI Special Steel from China . Any measure and special request could meeting . Very adequate stock could promote to abroad . Although this year the coronavirus have influenced to all over the world . But we belive that we could fight against from this . And resure the 1.2344 tool steel business relationship like before . And get the win-win cooperation in the future .

1.2344 Saw Cut Sheet Plate for Auto Parts Mould Use sales promotion in March .

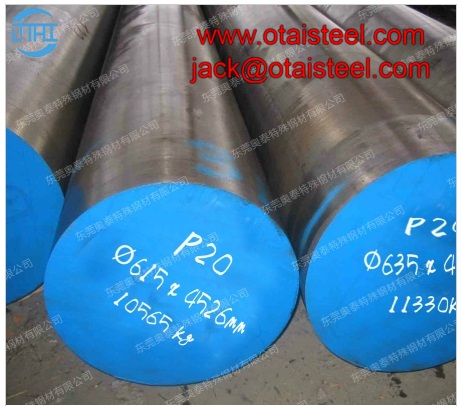

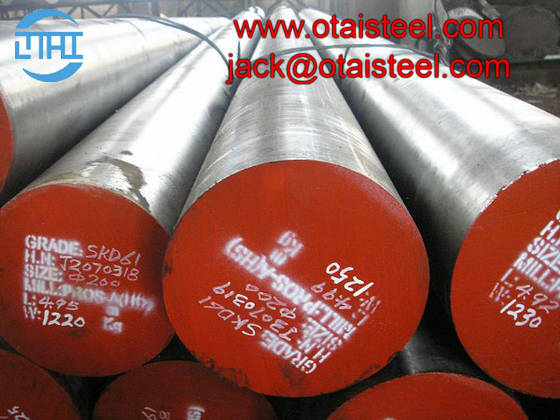

1.2344 tool steel metal china supplier and stockholders. OTAI Special steel is hot work alloy 1.2344 tool steel china supplier of in round bar, plate, flat bar, sheet, square and block. 1.2344 tool steel equivalent with JIS SKD61, GB 4Cr5MoSiV1 and AISI H13 Tool Steel. 1.2344 steel consists of chromium, molybdenum and vanadium and is known for its high hardenability and great toughness.

The molybdenum and vanadium act as strengthening agents while the chromium content helps the 1.2344 tool steel to withstand softening when used at high temperatures. It also combines shock and abrasion resistance, has good red hardness, can resist rapid cooling and withstand premature heat checking. 1.2344 tool steel has good machinability, good weldability and good ductility and it can be formed by conventional means. So 1.2344 steel applications is very range in hot forged mold, hot work tool.

1.2344 tool steel is characterized by:

- High level of toughness and ductility

- Good resistance to abrasion at both low and high temperatures

- Good high-temperature strength

- High through-hardening properties

- Very limited distortion during hardening

- Good resistance to thermal fatigue 1.2344 Saw Cut Sheet Plate for Auto Parts Mould Tool Steel is used in hot forging dies. hot forging die inserts, hot gripper dies, hot nut tools, hot header dies, brass forging and pressing dies, hot forging aluminum base dies . aluminum casting and extrusion dies, zinc die casting dies, extrusion mandrels, plastic molds. cores, die holder blocks, hot press dies, hot work punches, etc.

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: jack@otaisteel.com