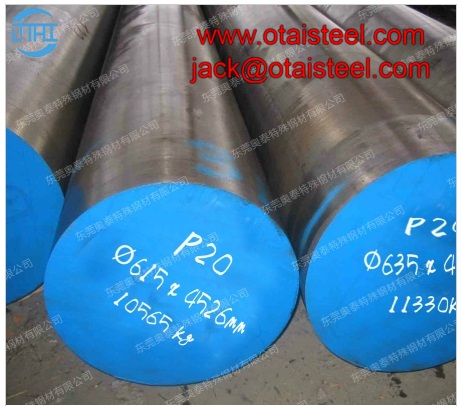

How to perform heat treatment on P20 steel?

If we know more about it ,we can take advantage of the p20 better. At the same time ,We can work efficiently.

heat treatment on P20 steel

The mass fraction of Mo in this steel reaches 0.46%, which can suppress the transformation of austenite to pearlite, improve the stability of austenite, and improve the hardenability and tempering resistance of steel. The simultaneous presence of Mo, Cr, and Mn can reduce or suppress the temper brittleness caused by other elements. If the mass fraction of Mo in the steel reaches 0.50%, the temper brittleness can be eliminated.

Mo has a solid solution strengthening effect on ferrite.and at the same time, it can improve the stability of carbides, improve the impact toughness and recrystallization temperature of the mold. that is, increase the creep resistance of ferrite at high temperature. It can effectively inhibit the cementite from growing up at 450 ~ 600 ℃ .It can promote the precipitation of dispersed special carbides, further strengthen the matrix, and enhance wear resistance.

what shall we pay attention to during heat treatment on p20 steel?

However, the high-temperature oxidation resistance of molybdenum (Mo) steel is poor. the protection of the die should be paid attention to during heat treatment. When Mo steel is heat-treated in a vacuum furnace, Mo will volatilize under a high vacuum. The vacuum should be adjusted in time. When the S element in the steel is high, low melting point eutectics of MoS and Fe will form, resulting in hot brittleness. Generally, Mo content When low, the impact is small.

This kind of steel is also called pre-hardened steel. that is, no heat treatment is performed after mechanical processing after quenching and tempering. The hardening and tempering temperature is 840 ~ 860 ° C, and the heat preservation coefficient is 30 ~ 45 s / mm. It should be preheated at 500 ~ 550 ° C to reduce thermal stress. The hardness after quenching the hot oil is 50 ~ 54HRC. 05 ~ 0.10μm. After tempering at 600 ℃ so that the hardness is controlled at about 30HRC for machining, the surface roughness after processing can reach Ra0. 05 ~ 0.10μm. The steel is added with S, Ca, B and other elements to become free-cutting steel. The hardness of heat treatment is controlled at 30 ~ 35HRC, which has good machinability and low surface roughness.