The improvement of H13ESR steel is an air-cooled hardened hot work die steel with high hardenability

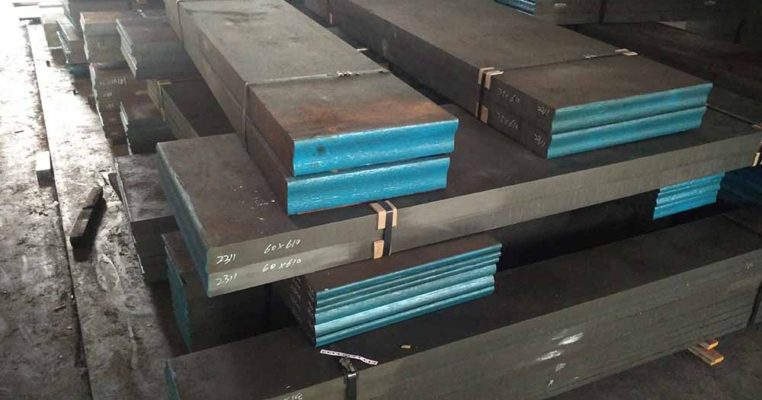

H13 ESR steel is an air-cooled hardened hot work die steel with high hardenability

Toughness and excellent thermal fatigue resistance. It is one of the most widely used hot work die steels in the world today. In service, hot work die materials need to withstand impact loads,and alternating cold and heat, often due to insufficient strength ,and toughness, especially poor lateral toughness, leading to early failure.

Therefore, improving the microstructure of hot work die steel ,and increasing its impact toughness can significantly increase the service life of the die. At present, researches on H13 steel abroad mostly focus on phase transformation kinetics,and heat treatment process, while the research on the effect of forging process on the structure ,and properties of H13 steel is rare.

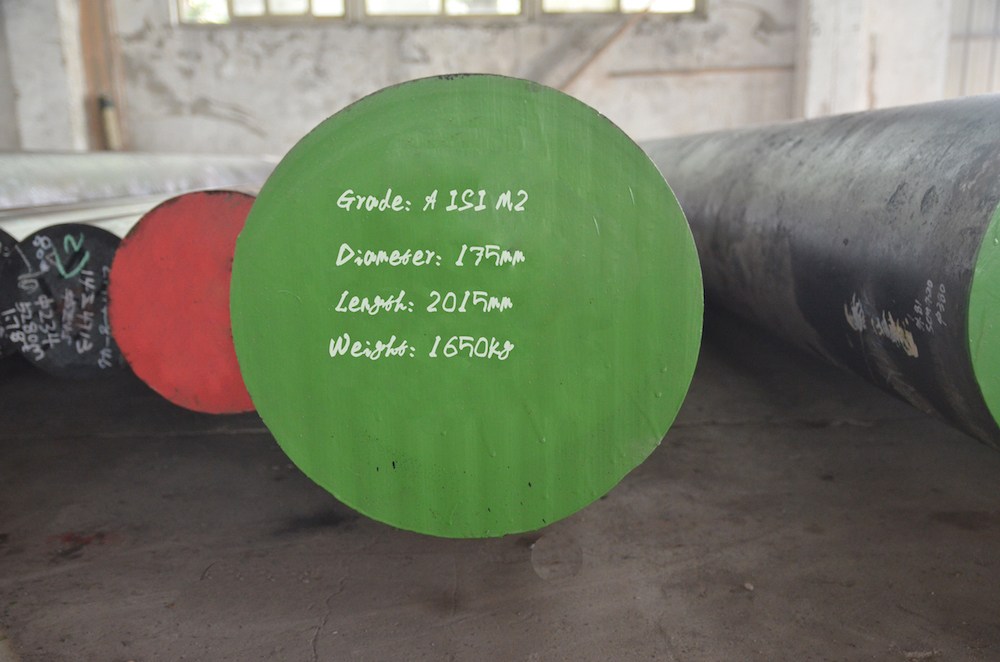

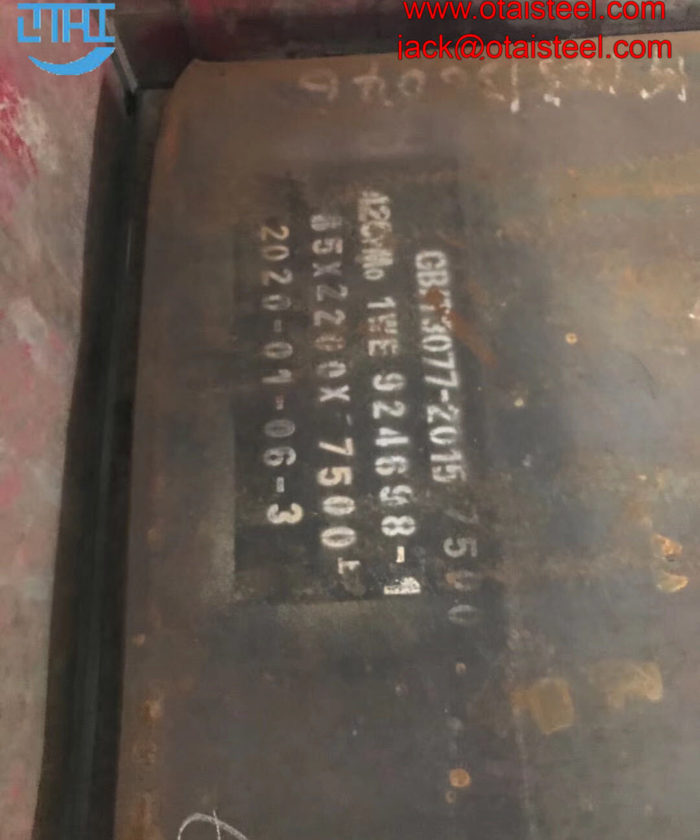

The researchers selected H13ESR for “one-up, one-draw” and “three-up, three-draw” forging processes. respectively, and made a comparative analysis from the aspects of microstructure ,and impact toughness to provide a certain reference,that for clarifying the choice of H13ESR steel forging process. The H13 steel ingot used in the test was smelted by the electroslag remelting process. The chemical composition of the steel ingot is as follows:

Chemical composition of H13ESR steel (wt%)

C: 0.32 ~ 0.45,

Si: 0.80 ~ 1.20,

Mn: 0.20 ~ 0.50,

Cr: 4.75 ~ 5.50,

Mo: 1.10 ~ 1.75,

V: 0.80 ~ 1.20,

p: ≤0.030S: ≤0.030

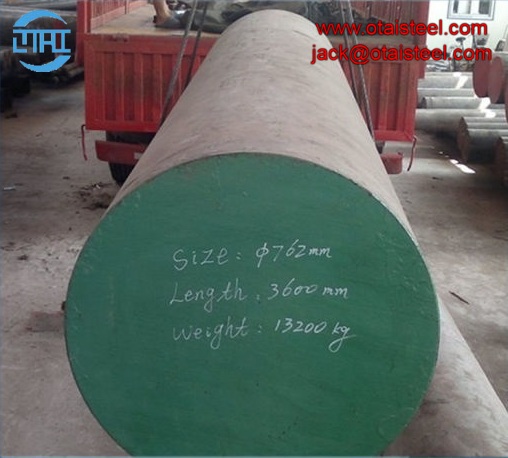

The initial forging temperature is 1180 ° C, the final forging temperature is 850 ° C, and the feed amount is controlled at 1/3 to 1/2 of the width of the lower anvil. The upsetting ratio is 3: 1, and the total forging ratio is 4: 1.Drawing and three upsetting, drawing. Samples were taken from the core of the steel ingot, and the as-cast microstructure was observed. A 10mm × 10mm × 55mm ,Charpy V-notch impact test specimen was taken at the core of the forging. The test specimen was quenched and tempered, (1030 ℃ for 30min, and tempered twice at 590 ℃ for 2h each time), and then,JB30B impact was used.

The impact test,it was performed on the testing machine, and the shape of the impact fracture,that was observed with a scanning electron microscope,which of JSM-6510 type. After forging the annealed metallographic specimens,it after being corroded by 4% nitric acid alcohol solution, the microstructure analysis ,which was performed with a Leica DM 2700M metallographic microscope.

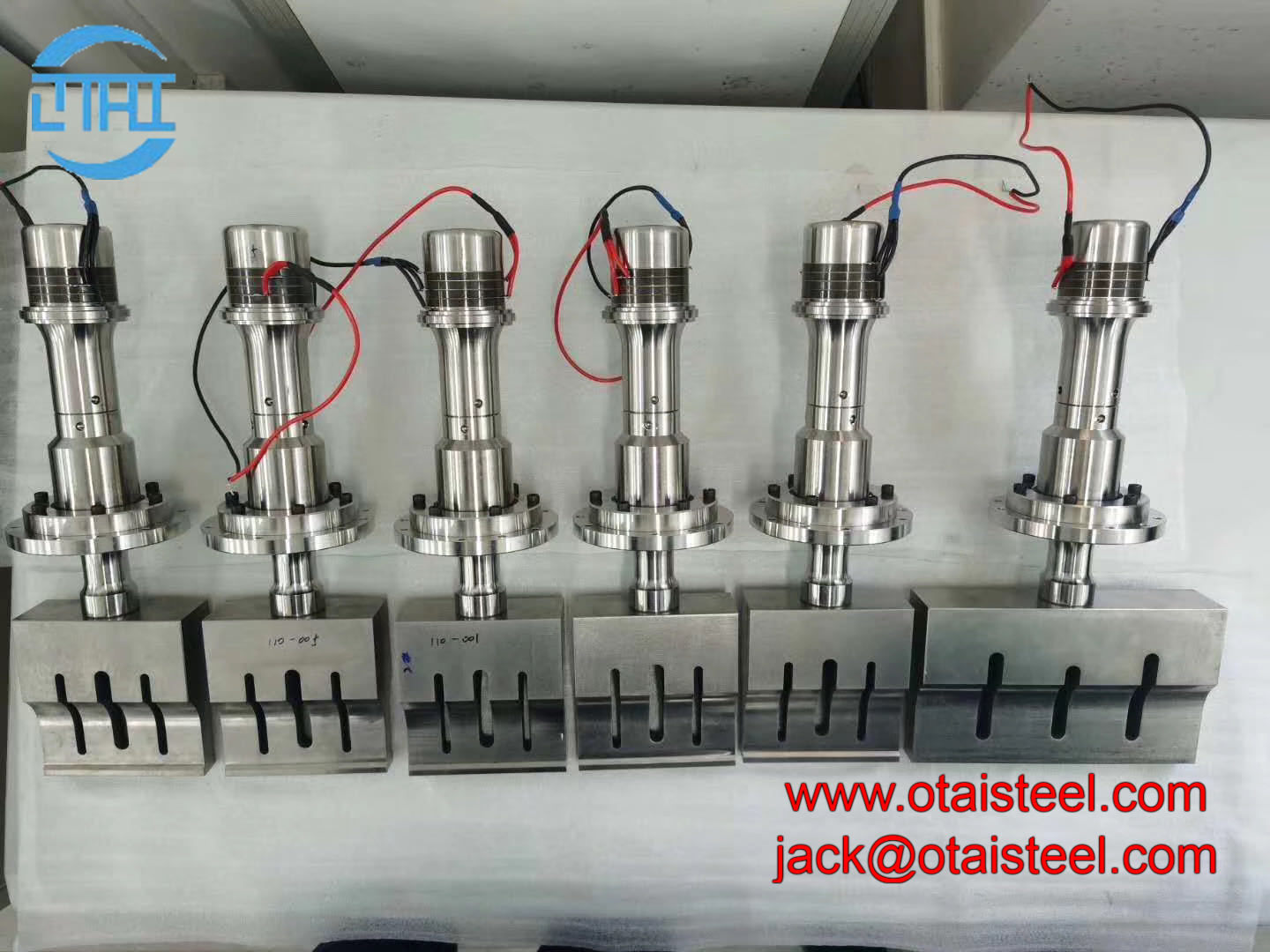

The results showed that:

(1) Compared with one-up and one-draw, after adopting the three-up and three-draw process, the microstructure of H13 steel is significantly improved, the grain is refined, the band segregation is significantly reduced, the carbide distribution is more uniform, and the material’s lateral impact performance is significant improve.

(2) The improvement of H13ESR steel,it is an air-cooled hardened hot work die steel with high hardenability,steel’s transverse impact performance is mainly,it due to fine grain toughening, band segregation, reduction of crystalline carbides, and more uniform carbide distribution, which weakens the tendency of crack initiation and other factors.

(3) Three pressing three drawing process ,it can significantly improve the structure of H13 steel ,and improve the impact performance. Therefore, three-pronged three-pronged is superior to one-pronged one.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com