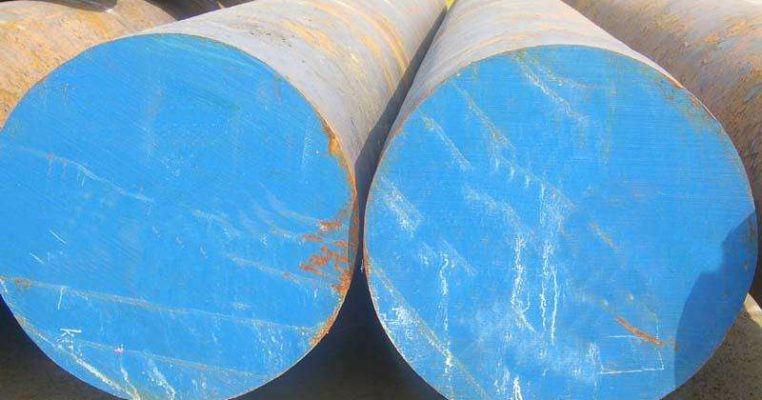

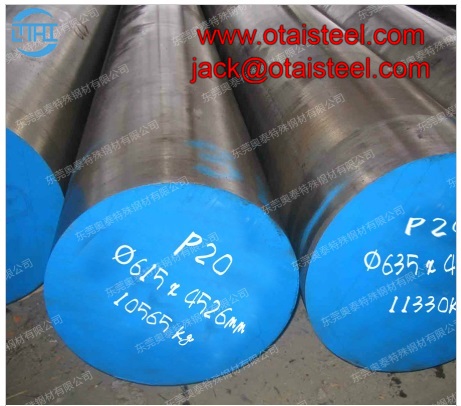

30CrNiMo8 Round Bar Diameter size : 20-130MM sales promotion .

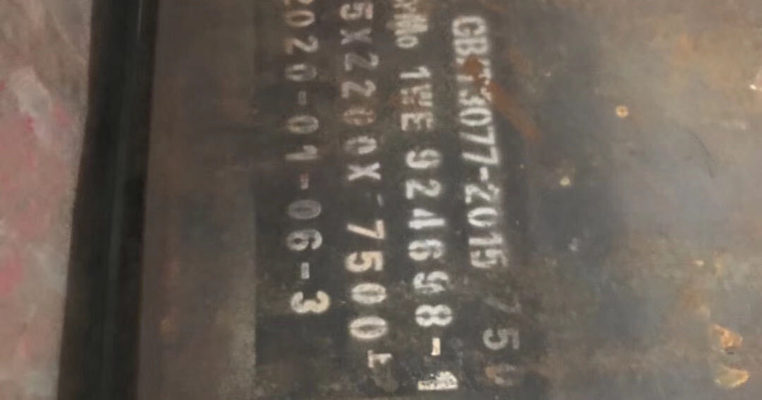

OTAI SPECIAL STEEL is 30CrNiMo8 alloy steel stockholders and suppliers from china . we have more 16 years experience in 30CrNiMo8 steel round bar, plate, steel flat bar, square supply.

30CrNiMo8 alloy steel is a high quality Quenched and Tempered Alloy Structural steel . It belong to the high quality medium carbon, Oil Quenched & Tempered Hardenss is 28-34 HRc.4340 Annealing delivery hardenss less than 250HB .

30CrNiMo8 Round Bar is a alloy structural steel, 30CrNiMo8 Round Bar is used for engineering structural . Used as require good toughness, high strength, as well as the important conditioning of large size, heavy machinery such as high load of axial . turbine shaft, larger than 250 mm in diameter of helicopter rotor shaft, turbojet engine turbine shaft, blade, high load of transmission parts, fasteners of the crankshaft .

30CrNiMo8 Round Bar is Gear, etc.; Can also be used for operating temperature over 400 ℃ of rotor shaft and blade, etc.; And after nitriding processing can also be used to make special performance requirements of the important parts, after low temperature tempering or can be used for ultra-high strength steel after isothermal quenching .

30CrNiMo8 Round Bar and flat sections can be cut to your required sizes. AISI 4340 tool steel ground bar can also be supplied, providing a high quality tool steel precision ground tool steel bar to your required tolerances. ASTM 4340 steel is also available as Ground Flat Stock / Gauge Plate, in standard and nonstandard sizes .

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: jack@otaisteel.com