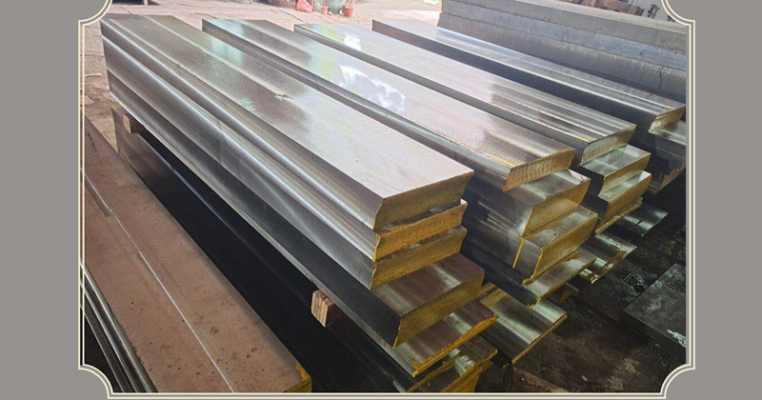

aisi 4140 plate equivalent: China suppliers, wholesale, distributors, and stockholder–Dongguan Otai Special Steel Co Ltd. We Otai is a manufacturer and has a large quantity of stock in our warehouse. We supply in Round bar, gauge plate steel, pipe, tube, rod, square, hexagonal, blanks, plate, sheet, precision ground flat bar. Including precision ground bar stock, hollow bar, we provide black surface and black surface alloy steel material.

1) 4140 steel belongs to the alloy structural steel. After Quenching & Tempering, its hardness is 28-34 HRC.

2) 4140 steel used for bending machine molds.

3) Besides, it can be used to under 2000m deep well of oil drill pipe joint and the fishing tool.

4) Also, it can be used for engineering structural parts, like high tensile shafts, gears, pinions, and spindles.

4140 hr plate: Its heat treatment has good strength and good comprehensive mechanical properties.

The common stainless steel’s chromium content is higher than 12.5%. So it has anti-rust performance. From the analysis of the composition, 4140 steel also has chromium. But its chromium content is only 0.8%-1.1%, which is far lower than the standard for rust prevention. Therefore, 4140 steel is not stainless steel. Please pay attention to its rust prevention when using it.

But 4140 steel can be used to make gears. Because lubricating oil is often used when gears are running. The lubricating oil can protect the gear from rust while protecting the normal operation of the gear.

News about the steel

In July this year, iron ore production in China came to 79.929 million mt. The prices indicated a further sharp decrease in August amid the central government’s target to decrease crude steel output and also amid significant decreases in ferrous metal futures prices. (aisi 4140 plate equivalent)

Otai provides the grinding, milling, polishing, turning, drilling, and other machining services as your required tolerances and size. (aisi 4140 plate equivalent: We keep a daily inventory of 1500 tons)

Otai does not act as a material handler. We possess proprietary technology and continuously iterate. We undertake every order to end and solve customer’s problems without any hesitation on responsibility. We are welcome to your kind inquiry.