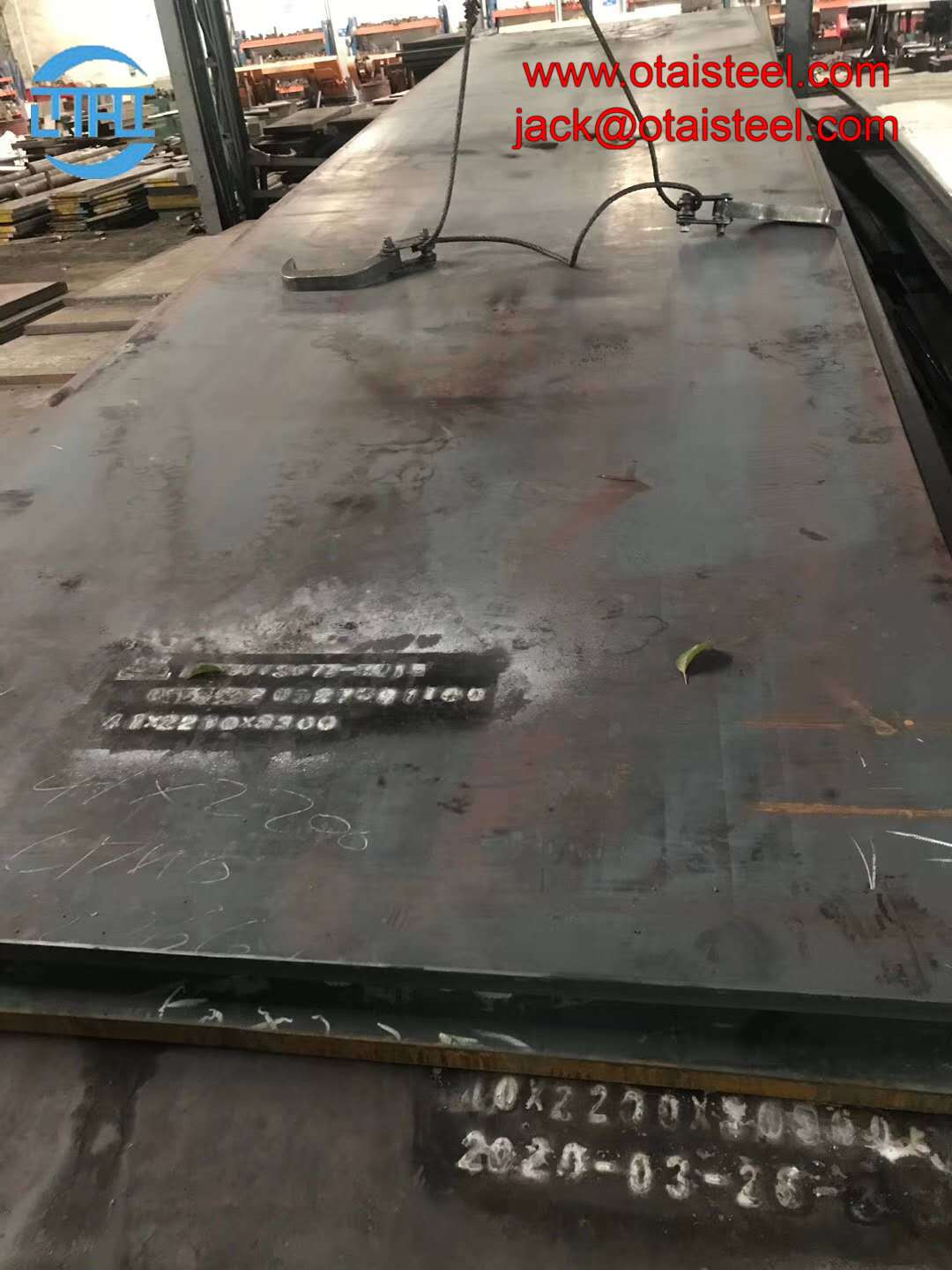

1.2312 Sheet plate suitable for make plastic mould , use for production high-end Auto Parts and phone parts . OTAI SPECIAL STEEL is Din W-Nr 1.2312 Tool Steel stockholders and suppliers from china. we have more 16 years experience in 1.2312 special tool steel plate, round, bar, flat bar, square supply.

1.2312 Steel is a high quality plastic tool mold steel . 1.2312 is 1.2311 add about 0.08% Sulphur improve free cutting ability of 1.2311 tool steel . It belong to the high quality medium carbon, Pre-hardness(28~34HRc) plastic mould steel . It needn’t further Make heat treatment for make plasitc injection moulding.

1.2312 tool steel properties is very simliar with ASTM AISI P20S steel . At most work environment,40CrMnMoS8-6/1.2312 steel is equivalent with P20S tool steel .

Related Specifications of Din WN-r 1.2312 tool steel material

Din W-Nr 1.2312 Tool Steel is a nice Plastic Mould steel . we can supply the 1.2312 round bar, steel flat bar, plate, hexagonal steel bar and steel square block . 1.2312 steel Round bar can be sawn to your required lengths as one offs or multiple cut pieces . Rectangular pieces can be sawn from flat bar or plate to your specific sizes . Ground tool steel bar can be supplied, providing a quality precision finished bar to tight tolerances…

1.2312 Sheet Plate Tool steel is a plastic injection mould steel material . the steel by “super clean” produce process, pre-hardened . showing the height of micro pure and excellent homogeneous structure . excellent polishing and light etching engraving . After heat treatment, processing and polishing performance is very good . can be carried out, and can be processed, suitable for the surface treatment of chrome, material hardness . good toughness, good mechanical processing performance . Gold microstructure is martensite and bainite structure . Main be applied to in plastic steel mold. like car injection moulding, PVC, PP plastic injection molding etc.

1.2312 tool steel round bar and flat sections can be cut to your required sizes. 1.2312 tool steel ground bar can also be supplied, providing a high quality tool steel precision ground tool steel bar to your required tolerances. 1.2312 steel is also available as Ground Flat Stock / Gauge Plate, in standard and nonstandard sizes.

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: jack@otaisteel.com