P20 mold and OT718 can be distinguished by the following formula: P20 + 1% Ni = OT718.

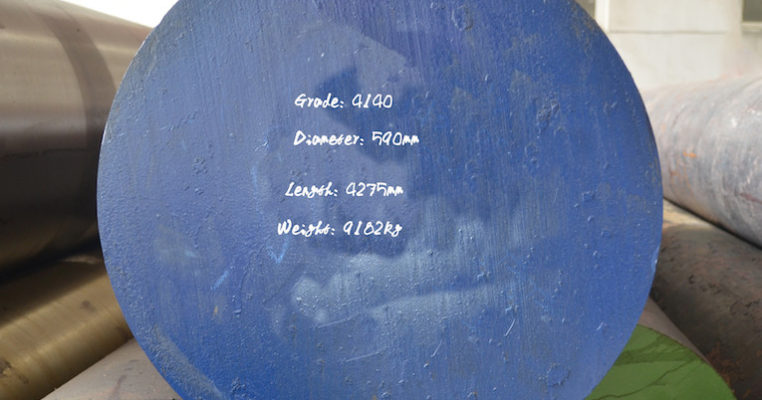

P20 mold and OT718 mold steel are universal pre-hardened mold steels, which are usually used for large and extra large plastic molds. OT718 die steel is equivalent to domestic steel number 3Cr2NiMo. P20 die steel is equivalent to 3Cr2Mo.Compared with P20 mold, OT718 die steel adds a small amount of Ni element. From P20 400mm maximum size to 1000mm maximum size, greatly improved Hardenability.

The hardness of P20 mold is 4HRC lower than that of OT718 mold steel.

OT718 has better polishing performance and can be used to manufacture plastic molds with polishing requirements. P20 mold steel can usually be used for plastic molds or plastic molds that are not required.

There are also improved P20 die steels, one is to add Ni to improve the uniformity and corrosion resistance. And the other is to add S to improve the workability and make it more suitable for mass production. As the most commonly used plastic mold steel in China, the domestic technology is already very mature.And most steel mills have produced high-quality products. As long as the purity of the mold steel reaches the standard, and the domestic production is also very easy to use.

1.2738 is a commonly used German standard plastic mold steel, usually referred to as 738 for short. This steel is more popularly called OT718. It is generally tempered and pre-hardened to HRC28 ~ 36. After being processed into a mold, it is used directly without heat treatment.

OT718 Performance characteristics.

①Excellent polishing and photo-etching performance.

②Good machining performance.

③High purity and uniformity.

④ Uniform hardness.

⑤ Subsequent nitriding treatment or local flame quenching can be carried out to improve surface strength and surface wear resistance, and reduce surface failure.

Compared with the traditional plastic mold steel P20, 1% nickel is added to OT718, has better toughness and hardenability. And it is more excellent in large cross-sectional molds. This steel type is suitable for large-scale plastics, especially those with thickness greater than 400mm.

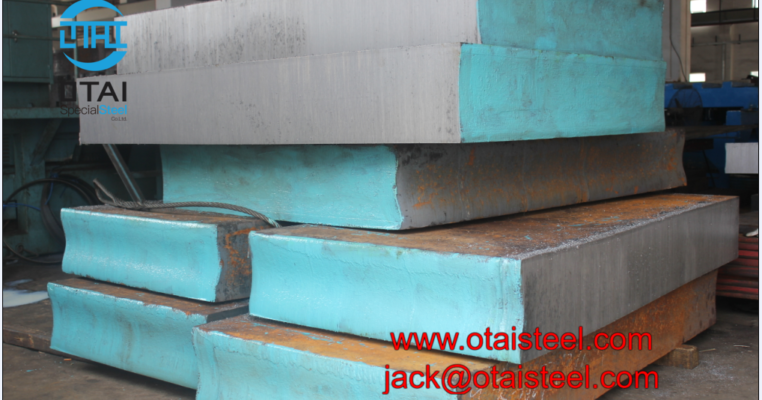

Recently, the mould steel request are increasing for fulfilling the mould tools on the different machines used on the anti-coronavirus.For supporting the work , our company make the special offer on the P20 steel plate during these days. It is the very good time to seize the rare chance to purchase this mold steel if you have any purchasing plan recently.

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: jack@otaisteel.com