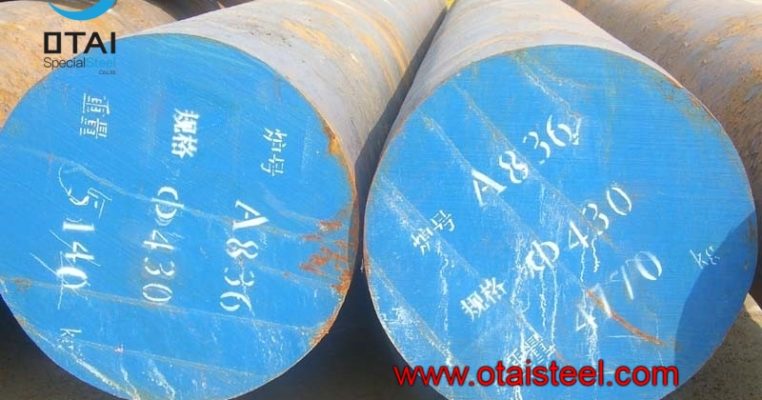

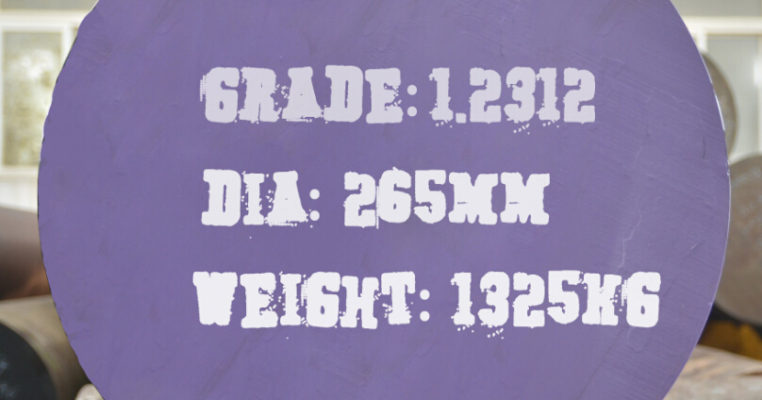

OTAI Special steel supply the steel plates, steel sheet, round bar, flat bars and steel coil for the Alloy steel, tool steel and carbon steel.

OTAI have the large stock available for the 42CrMo4, AISI 4140 and 1.7225 steel coil, and the thickness is ranged in 3~10mm, and the width size in 1260~1500mm. We exports various tool steel and alloy to more than 35 countries from Europe and America, Middle East and Asia. Our steel coil materials meet DIN / ASTM / EN / JIS etc different international standards.

Recently, when I talked with my one customer, he said he notice that the increase of new cases in China is Minimum. Did China find a special medicine for fighting the virus?Here I would like to share the facts as below. I think it is important to help people understand exactly why the case mortality number and the absolute death toll number in China has been so low.

For 76 days, the Wuhan city was under strick lockdown. Not the kind of lockdown where if you choose to stay in place, you stay in shelter you can. If you want to go out, you could also try to do that. No, for the great majority of the lockdown, people had to stay at home. Think about what happened in the United States, some people still have to go to work. Some people are against sheltering in place. Some people wear masks, others don’t. In Wuhan, it almost becomes an instinct to wear mask. If you go out without wearing mask, you feel strange. It is that kind of awareness to help yourself to help others. That really helps cut the path of the contagiousness of the virus. In a matter of a week or two, over 40,000 medics came all over China to Wuhan.

In China, we never had the discussion of herd immunity. We never had the discussion between keeping the economy going or saving lives. From the beginning, it was very clear that every life mattered. In Wuhan, over 3600 people aged over 80 survived. Among them, 7 people aged over 100 survived. I think that is probably a record for anywhere in this world.

And everything for the treatment fee is for free for Chinese infected people as government and country will pay for it.

And then of course, there is a role of traditional Chinese medicine. In some of the temporary hospitals where only people with mild symptoms were being treated. They were only given traditional Chinese medicine. This is an advantage that China enjoys.

Is something again probably won’t be understood so easily by people in the west or in America or in Europe. It is the kind of trust between the authorities and the local residents. They trusted in the measures that they were told to follow. And the measures worked.

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: jack@otaisteel.com