EN24 steel and mild steel

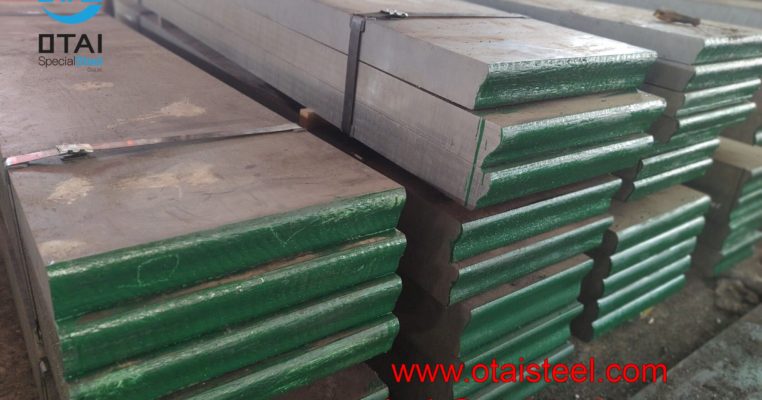

Otai exports various tool steel and alloy to more than 30 countries from Europe and America, Middle East, and Asia. Our steel materials meet DIN / ASTM / EN / JIS etc different international standards. Special Steel supplied by Otai is fully trusted by the US oil field giant and one military industry well-known enterprise. Today we will talk about EN24 steel and Mild steel’s difference and application.

EN24 steel is a kind of alloy structural steel – mechanical steel.

The first is to improve the hardenability of steel, to ensure that the steel after heat treatment to obtain a good comprehensive mechanical property, with high strength and enough toughness.

Suitable for cold pressing, thin blanking dies, punch and shear die. It is also suitable for manufacturing precision molds, precision instruments, precision side setting tools, reamer, milling cutter, roller, cold-drawn die, GAUGE, sample die, punch, cold-cut, scissors, tungsten knife, woodworking tools, spiral touch, various punching die and so on.

Mild steel is also known as mild steel because of its low strength and hardness.

It includes most ordinary carbon structural steel and a part of high-quality carbon structural steel, most of which are not used for engineering structural parts by heat treatment, some by carburizing and other heat treatment for mechanical parts requiring wear resistance.

The annealing structure of low carbon steel is ferrite and a small amount of pearlite. Therefore, its cold forming ability is good, can be used to roll, bend, stamping, and other methods of cold forming. The steel also has good weldability. The carbon content ranges from 0.10% to 0.30%. Low carbon steel is easy to be processed such as forging, welding, and cutting. It is often used to make chains, rivets, bolts, and shafts.

Otai undertakes every order to end and solve customer’s problems without any hesitation on responsibility. When customized special steel is hard to get, Otai settles satisfactorily completely.