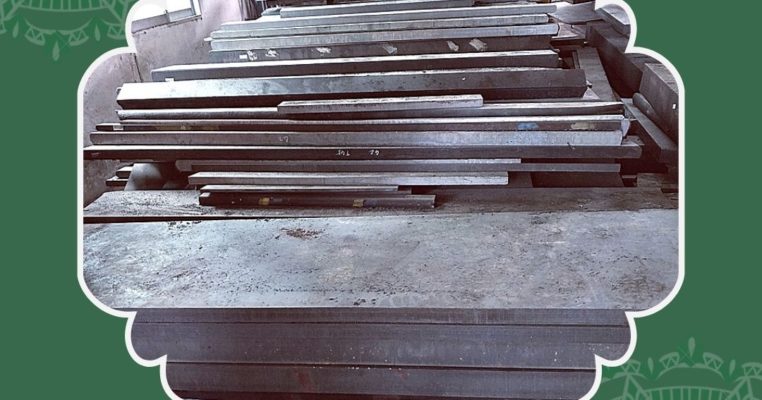

How many tons of EN19 hot rolled plate in our stock?

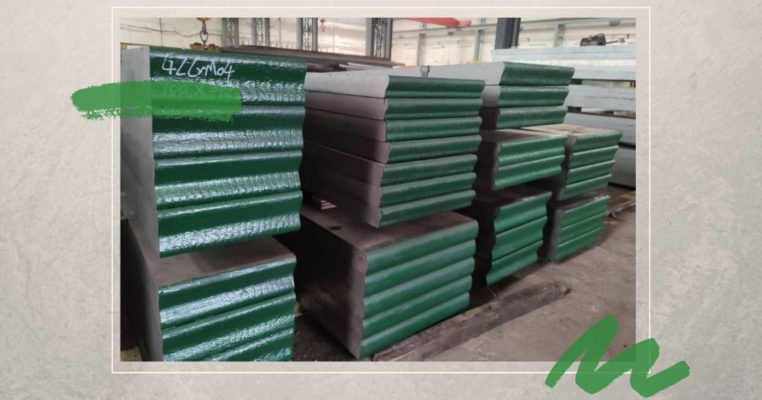

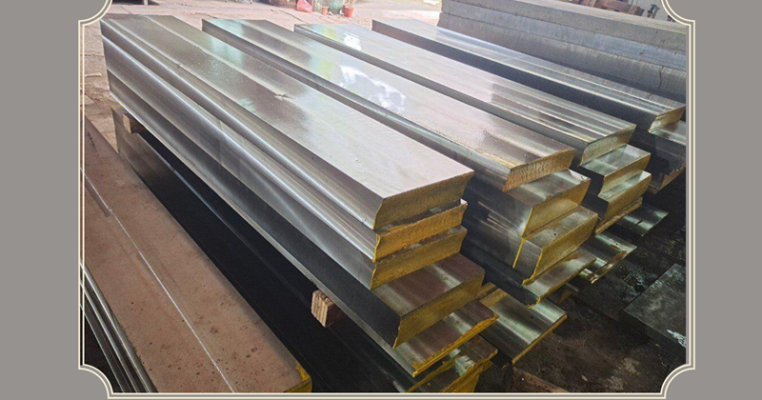

With over 20 years’ pre-sales and after-sales special steel, Otai helps distributors and end-users to avoid all possible swindle and cheat. Our steel materials meet DIN / ASTM / EN / JIS etc different international standards. Otai’s EN19 hot rolled plate: we keep a daily inventory of 1000 tons which is hard for competitors.

EN19 alloy steel, the steel has good workability, machining deformation of small, anti-fatigue performance is quite good.

On the hardenability of steel, EN19 heat treatment has good strength and good comprehensive mechanical properties, good manufacturability, high yield. The highest temperature is 427 degrees Celsius. EN19 strength, high hardenability, and good toughness, quenching deformation of small, high temperature creep rupture strength, and high. It is used for manufacturing forgings with higher strength and larger tempering cross-section than 35CrMo steel, such as big gear for locomotive traction, supercharger drive gear, rear axle, connecting rod and spring clamp with great load, also can be used for drilling pipe joint and fishing tool of oil deep well below 2000m, and can be used for bending machine mold, etc.

Customer’s story

We would like to share a real case of our customer with you. Gray from Germany sent us an inquiry for EN19 steel plates. As time is tight, he needs to receive the goods within 45 days. That’s no problem for us because we keep a daily inventory of 1000 tons. After the customer placed his order, we have prepared his EN19 steel plates to ready the next day. We also assisted the customer to find the fastest delivery, and the goods were delivered to the customer in 45 days.

8 consecutive years no quality event complain, over 80% repeat order rate. Otai undertakes every order to end and solve customer’s problems without any hesitation on responsibility. When customized special steel is hard to get, Otai settles satisfactorily completely.