D2 cold work steel -What is the D2 tool steel’s mechanical properties?

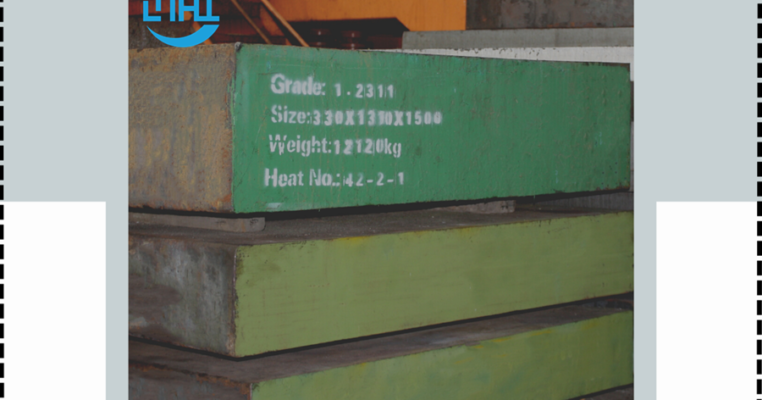

With over 20 years’ pre-sales and after-sales special steel, Otai helps distributors and end-users to avoid all possible swindle and cheat. Our steel materials meet DIN / ASTM / EN / JIS etc different international standards. D2 tool steel, we can supply the round bar, flat bar, plate, and square block.

D2 is a high carbon-high chromium alloy tool steel that offers great wear and abrasion resistance, due to the large volumes of carbides in its microstructure.

It is widely used in long production cold work applications requiring very high wear resistance and high compression strength. D2 tool steel is machinable in its annealed condition, and like other air-hardening tool steels, shows minimal distortion when treated with heat. D2 Tool Steel is available in rounds, flats, and squares, as well as ground flat stock and drill rod.

D2 cold work steel used for cutting, shaping and pruning is dead, gauge, longitudinal cutting knife, wearing parts, the texture is dead, thread rolling, drawing die, the rotary die cutter, knurling, bending modulus, gauge, the shear blade, polishing tools, volume, machine parts and control parts, injection screw and prompt components, sewing, extrusion die, tire shredder, etc.

Customer’s story

We would like to share a real case of our customer with you. Dave from Pakistan sent us an inquiry for D2 steel plates. As time is tight, he needs to receive the goods within 45 days. That’s no problem for us because we keep a daily inventory of 1000 tons. After the customer placed his order, we have prepared his D2 steel plates to ready the next day. We also assisted the customer to find the fastest delivery, and the goods were delivered to the customer in 45 days.

8 consecutive years no quality event complain, over 80% repeat order rate. Otai undertakes every order to end and solve customer’s problems without any hesitation on responsibility. When customized special steel is hard to get, Otai settles satisfactorily completely.