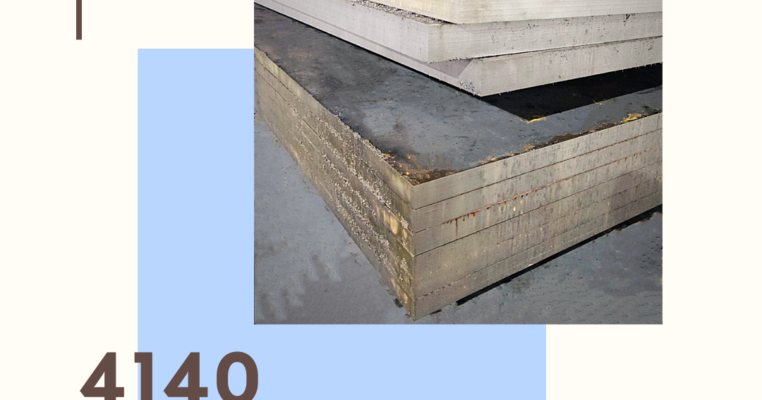

plate 4140 heat treated : We keep a daily inventory of 1500 tons

4140 alloy steel flat China suppliers, wholesale, distributors, and stockholder–Dongguan Otai Special Steel Co Ltd. We Otai is a manufacturer and has a large quantity of stock in our warehouse. We supply in Round bar, gauge plate steel, pipe, tube, rod, square, hexagonal, blanks, plate, sheet, precision ground flat bar. Including precision ground bar stock, hollow bar, we provide black surface and black surface alloy steel material.

4140 plate machinability: Its heat treatment has good strength and good comprehensive mechanical properties.

On the hardenability of steel, 4140 heat treatment has good strength and good comprehensive mechanical properties, good manufacturability, high yield. The highest temperature is 427 degrees Celsius. 4140 strength, high hardenability, and good toughness, quenching deformation of small, high temperature creep rupture strength, and high. It is used for manufacturing forgings with higher strength and larger tempering cross-section than 35CrMo steel, such as big gear for locomotive traction, supercharger drive gear, rear axle, connecting rod, and spring clamp with great load also can be used for drilling pipe joint and fishing tool of oil deep well below 2000m and can be used for bending machine mold, etc.

News about the steel

Under the rising cost, the domestic market( plate 4140 heat treated) has maintained a rising trend of shock since the beginning of 2021. In March, the cost support has weakened, the steel market has opened the destocking cycle, and the downstream demand has increased, which has brought support for the upward trend of steel stocks.

Otai provides the grinding, milling, polishing, turning, drilling, and other machining services as your required tolerances and size.( plate 4140 heat treated:We keep a daily inventory of 1500 tons)

Otai does not act as a material handler. We possess proprietary technology and continuously iterates. We undertake every order to end and solve customer’s problem without any hesitation on responsibility. We are welcome to your kind inquiry.