4140 plate thickness –1~10mm, Cold Rolled, Fast Delivery | OTAI

What is 4140 steel

4140 alloy steel is a chromium molybdenum alloy steel specification widely used in general purpose high tensile steel for components. For example, axles, shafts, bolts, gears, and other applications.

Similar to alloy grade AISI 4130 chrome moly alloy steel but with slightly higher carbon content.

The higher carbon content of 4140 steel gives greater strength and heat treatment capabilities in comparison to AISI / ASTM 4130 alloy steel.

However, it does have inferior weldability characteristics.

Steel news

At present, nine counties and cities in Tangshan have lifted the management of regional blockade control.

The clustered epidemics in many places in China have dragged down the production and operation of the manufacturing and construction industries. In the short term, the demand for steel has been unstable, and the rise in steel prices is insufficient.

Once the social “dynamic clearing” is realized in various places, the demand for steel will be released retaliatory, the demand growth may be higher than the supply, the inventory will enter a stage of decline, and there may still be room for steel prices to rise.

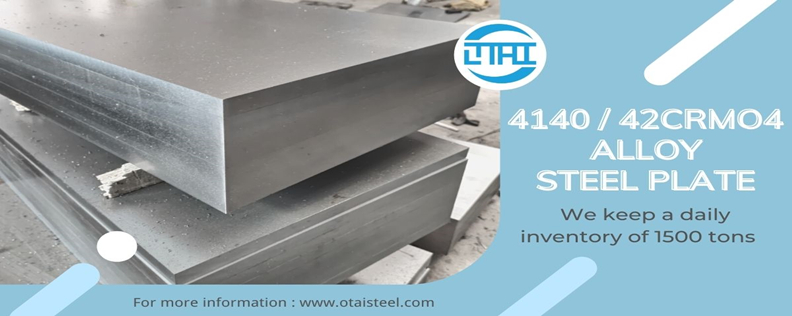

Why Choose OTAI

1)All year round, Otai can guarantee our 4140 flat stocks are more than 1500 tons. Different thicknesses and lengths can be customized.

2)After placing an order, shipment can be arranged immediately.

3)Otai is a leading China supplier of 4140 steel, working with Uddeholm, Thyssenkrupp, with ISO9001 certified.

Customer’s story

We would like to share a real case of our customer with you. Jay from Brazil send us an inquiry about the 4140 sheets, which required a lot of specifications and a small quantity. James asked many suppliers who were unwilling to cooperate and finally found us. We are the source manufacturer so that we can meet the needs of customers to customize the specifications of goods. Then James placed the order successfully. After receiving the goods, he said that he would seek our cooperation for a long time. (4140 plate thickness)

FAQ

Is 4140 steel stainless steel?

NO. it’s alloy steel.

Is 4140 good for forging?

4140 has high strength, hardenability, good toughness, small deformation during quenching, high creep strength, and long-lasting strength at temperature.

What is 4140 QT?

As a quality alloy steel grade 4140 is commonly supplied quenched and tempered (QT) which offers good high tensile properties. It is characterized by its good ductility and shock-resistant properties that combine with good wear resistance.

What is 4140 steel used for?

It can be used for manufacturing forgings with higher strength and larger tempering cross-section than 35CrMo steel, such as big gear for locomotive traction, supercharger drive gear, rear axle, connecting rod, and spring clamp with great load and etc.

What is the hardness of 4140?

It is offered in the cold finished annealed condition. Typical hardness is Rockwell “C” 19/24. Typical tensile strength 114,000 PSI. Its wear-resistant properties far exceed that of “cold roll” steels.