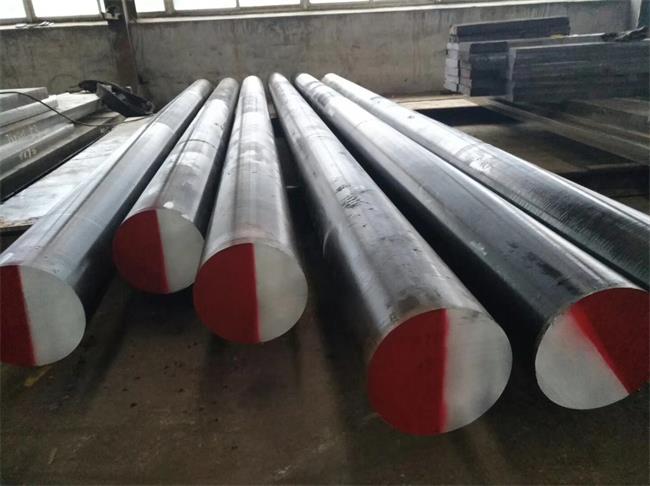

Today, we have a nice talking about our company’s steel with a Mexican customer. During the communication process, the customer is quite sure about the chemical composition and quality of our steel. Our company is a professional supplier of tool steel, die steel, and alloy steel.

The following is a brief introduction to tool steel

Tool steel is steel used to make cutting tools, gauges, molds and wear tools. It has high hardness and high hardness and red hardness at high temperatures, as well as high wear resistance and proper toughness.

Tool steels are generally classified into carbon steels, alloy steels, and high-speed steels

The steel used in the manufacture of various cutting tools, cold and hot deformable tools, gages and other tools, collectively referred to as tool steel. Various steels have common requirements, such as high hardness, good wear resistance, and certain toughness and strength, and have their own special requirements, such as red hardness, impact resistance, dimensional stability, thermal fatigue resistance, and good overall mechanical properties, etc. In order to meet these different requirements, steels of various compositions are produced and their performance requirements are met by appropriate heat treatment processes.

The steel used in the manufacture of various cutting tools, cold and hot deformable tools, gages and other tools, collectively referred to as tool steel. Various steels have common requirements, such as high hardness, good wear resistance, and certain toughness and strength, and have their own special requirements, such as red hardness, impact resistance, dimensional stability, thermal fatigue resistance, and good overall mechanical properties, etc. In order to meet these different requirements, steels of various compositions are produced and their performance requirements are met by appropriate heat treatment processes.

High-speed steel:

High-speed steel is an alloy steel containing C, Mn, Si, Cr, V, W, Mo, Co. And it can be used for high-speed rotary cutting tools, which can wear and high temperature, which is the proportion of Cr, V, W, Mo. In addition, the ratio of Cr and V must not be less than 3%. The P and S content should not exceed 0.030%.

Alloy steel:

The processing methods of alloy tool steel are mainly pressure- machined steel and cutting tool steel. There are many types of alloy tool steels, such as cold work, hot work, non-magnetic, plastic mold steel, etc., while the ratio of Cr and V cannot be too low.

Cold work steel:

Cold steel selection, in practical applications, tool steel is selected according to the main failure mechanism of the mold. It is not enough to choose tool steel to have only knowledge of steel properties. It is also necessary to consider the number of parts produced, the type of material being processed, the thickness and hardness. One of the basic methods for selecting steel is to completely eliminate all failure mechanisms other than wear, and then select the steel with the best wear resistance to meet the production requirements.