What are the characteristics of H13 die casting molds?Mr Chen asked me today.

I told him,H13 is a very representative hot-making mold steel. It is widely used in die casting molds. The operating temperature below 600 degrees, the comprehensive performance is good,and the heat resistance is strong, and it can be water cooled directly , Heat treatment hardness up to HRC50-54, excellent toughness, suitable for all hot-working die-casting molds, mainly used for 50,000 times molds, aluminum alloy die-casting molds, all of the zinc alloy die casting molds, requiring long service life.wear-resistant plastic molds, All wear-resistant parts that require high-temperature operation.

If you wanna know more about material of die casting molds,please click our link- Die casting molds ,or see information as below,

Related Specifications ASTM A681-1999 H13 Tool Steel data files Down

1. AISI H13 tool steel Chemical composition

| C(%) | 0.32~0.45 | Si(%) | 0.80~1.20 | Mn(%) | 0.20~0.50 |

| P(%) | ≤0.030 | S(%) | ≤0.030 | Cr(%) | 4.75~5.50 |

| Mo(%) | 1.10~1.75 | V(%) | 0.80~1.20 |

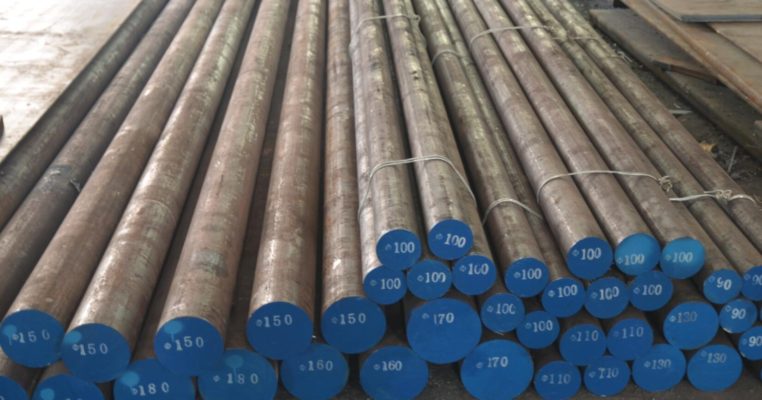

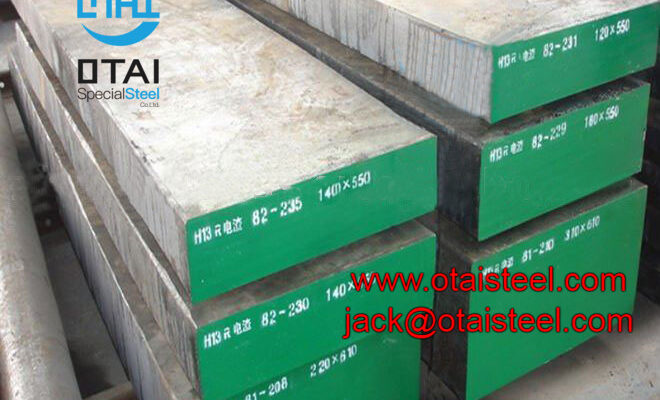

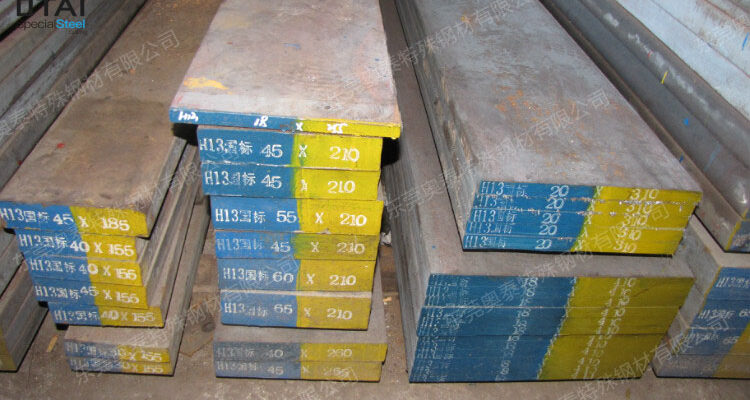

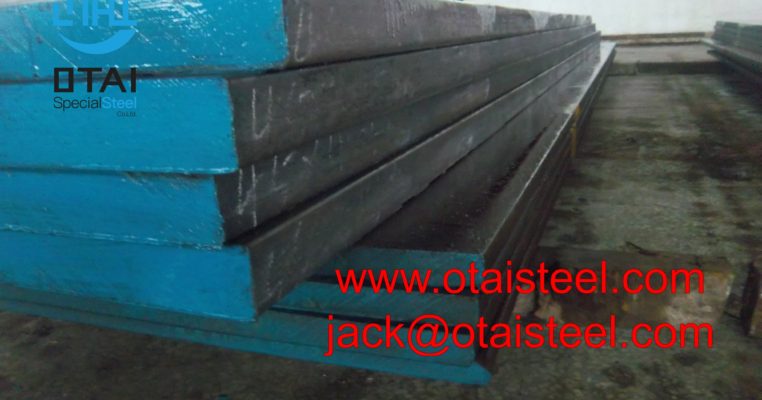

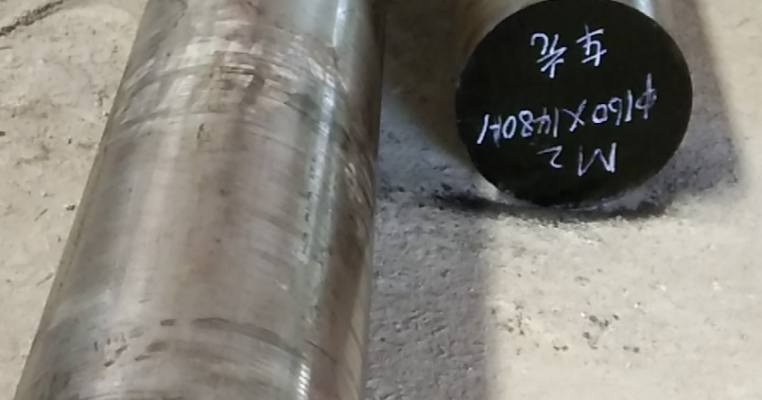

2. AISI H13 tool steel Form of Supply

we can supply the round bar, flat bar, plate and square block. round bar can be sawn to your required lengths as one offs or multiple cut pieces. Steel plate and sheet rectangular pieces can be sawn from flat bar ,sheet or plate to your specific sizes. Ground tool steel bar can be supplied, providing a quality precision finished bar to tight tolerances.

- Round

- sheet

- Plate

- Square

Surface Finish: Black, Rough Machined, Turned or as per given requirements.

3. Applications of AISI H13 Tool Steel

H-13 Tool Steel is used in hot forging dies, hot forging die inserts, hot gripper dies, hot nut tools, hot header dies, brass forging and pressing dies, hot forging aluminum base dies, aluminum casting and extrusion dies, zinc die casting dies, extrusion mandrels, plastic molds, cores, die holder blocks, hot press dies, hot work punches, etc.

4. AISI H13 Steel Forging

For forging H13 tool steel, first slowly Preheat to 750°C(1382°F), soak enough time, then rapidly heat to 1050-1100 °C(1922-2030°F). then start forging, ensure the forging temperature higher than 850°C(1562°F). Cool H13 tool steel must be slowly after H13 steel forging finished.

5. Annealing of Tool Steel H13

Heat to 840-860°C(1544-1580°F), Soak thoroughly before furnace cool at a maximum rate of 20°C(68°F) / hour, Cool down to 600°C (1112°F). Then cool in air.

6. Stress Relieving

Befor make products, The Tool steel stress relieving is very necessary. When H13 tool steel is ground , heavily machined, cutting,milled , the relief of internal strains is necessary before hardening to minimise the possibility of distortion. for stress relieving, heat the H13 steel component to 700°C(1292°F) carefully, Get enough soaking period . Then cool in the furnace or cool in air.

7. Hardening

first should preheat the H13 tool steel parts to 780-820°C(1436-1508°F), Soak enough time, ensure soak thoroughly. then rapidly heat to 1000-1030°C(1832-1886°F), soak about 30 mins. cool in air or oil.

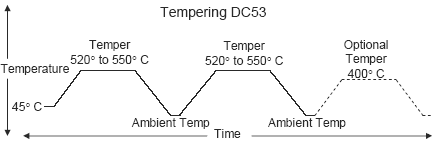

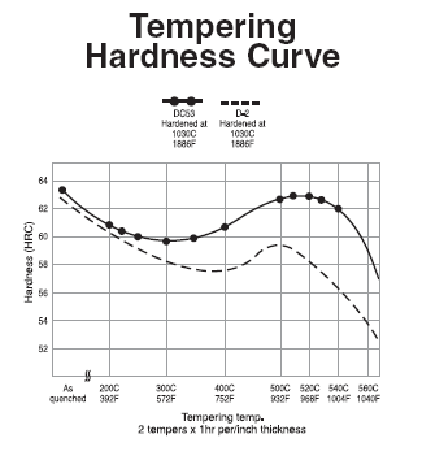

8. Tempering

Heat the H13 tool steel parts to tempering temperature, soak enough time until to Soak thoroughly. The usual tempering temperature range is 400-650°C(752-1202°F), It depend on the tools hardness require and the operating temperature. H13 tempering data for your reference as below:

| Temperature [°C] | 400 | 500 | 550 | 600 | 650 |

| Hardness [HRc] | 54 | 56 | 54 | 49 | 47 |

9. Nitriding of H13 tool steel

On some special tool require, the higher hardness is required. Nitriding the H13 steel can get a hard surface case. after Nitriding , the H13 hot work tool steel will have a resistant to wear and erosion surface. Typical Nitriding data for your reference as below:

| Temperature | Time | Approx. Depth of Case |

| 525°C | 10 hours | 0.125mm |

| 525°C | 20 hours | 0.180mm |

| 525°C | 40 hours | 0.250mm |

| 525°C | 60 hours | 0.300mm |

What are the characteristics of H13 die casting molds?Mr Chen asked me today.

Ms Sharon Wan

Mobile/WhatsApp: 0086-13580960968

Tel: 0086-769-23190193

Fax: 0086-769-88705839

Email: Sharon@otaisteel.com